Construction

Construction of the University Sciences Building began October 7, 2009 and is scheduled for Substantial completion on approximately July 1, 2011. Turner Construction Company is the construction manager at risk. The delivery method is Design-Bid-Build with a competitive bid, Stipulated Lump Sum contract valued at $49,689,001 according to the owner’s website. The overall estimated cost of construction is approximately $52.1 million. The project is being designed and constructed under enhanced commissioning requirements to meet LEED specifications.

Electrical

Incoming power is provided from the campus 13.2kV service via 3-#4/0 wires to the switchgear in basement electrical room of the University Sciences Building. This service feeds a main transformer, located in the 5th floor electrical room, which provides the 5000-amp, 277/480V 3-phase main panel and supports critical mechanical loads, emergency panels, and substation loads. There is a 150kVa 120/208V transformer that serves receptacle panels. Upon utility power failure, there are two automatic transfer switches (ATS-1 and ATS-2) which will send a start signal to the Emergency Diesel Generator to maintain power to the Emergency Panel and Main Standby Panel for Life Safety Systems and Emergency Lighting Systems. There is also a Fire Pump Transfer switch to provide power to the fire pumps in case of emergency. The Diesel Generator is 600kW, 480V, 3-phase with a 0.8 power factor and 750kVA.

Lighting

The lighting system includes a variety of different fixture types and sizes. The layouts generally include T8 Linear Fluorescent fixtures which are surface mounted, recessed into the ceiling, or direct/indirect pendant mounts. The lamps are predominantly 4 foot long units arranged end-to-end in strips. This holds constant in classrooms, auditoriums, teaching labs, offices, and student lounges. The linear fluorescent fixtures are accented by compact fluorescent downlights and a variety of other lamp styles. There are interior LED accents as well as outdoor LED and Metal Halide fixtures.

Interior lighting control is performed by wall-mounted switches, occupancy sensors, timer switches, and dimmable lighting control systems. Occupancy sensors are installed in restrooms, offices, public corridors and other public areas. This prevents use of fixtures without occupancy, and energy savings as a result. Timed switches are used for the same purpose in irregularly occupied spaces such as mechanical electrical rooms. Dimmable lighting ballasts are installed in the large rooms including the 240-seat auditorium, conference and seminar room and large classrooms. During power failure, designated emergency fixtures and exit signs remain illuminated for egress purposes.

Mechanical

The HVAC system that serves the University Sciences building is a Variable-Air-Volume (VAV) system consisting of nine Air Handler Units (AHUs).The air handlers use Chilled Water coils and Glycol Heating coils as well as MERV-8 rated filters. The VAV system uses terminal reheat as necessary as well as Supply Air Modulation. Supply air flow rates are based on ASHRAE Standard 62.1. The Laboratory spaces will be supplied with 100% Outdoor Air for Indoor Air Quality. Heat Recovery Loops will be used to increase the overall building efficiency by an estimated 29%, which is well above the required 14% for LEED certification.

The Chilled water system consists of a Primary/Secondary chilled water system with two 620-ton Electric Centrifugal Chillers consuming 375kW each at full capacity. The chillers will use the refrigerant HFC-134a. The condensing system includes two 620-ton Induced Draft Single Cell Cooling Towers each powered by 40 horsepower motors.

Heating coils are supplied by the campus steam system. Steam is supplied to the system at 200psi and goes through two pressure reducing valves from 200psi to 60psi and then 60psi to 12psi. Steam is used to heat a 30% glycol mixture for the heating coils and some steam is used for humidification in the air handling units. Supplementary heating needs throughout the building are met by Electric Unit Heaters and hot water radiant panels.

For domestic water use, there are two 250-gallon hot water tanks in the basement mechanical room which are heated by the steam distribution system. A 30-gallon electric water heater provides supplemental heating to maintain a non-potable hot water loop temperature. There is a Reverse Osmosis multiple purification water tank on the penthouse level. For service to the laboratories, there is piping throughout the building for Carbon Dioxide, Nitrogen and Natural gases.

Structural

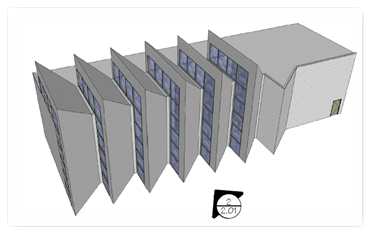

The structural design of the Integrated Sciences Building is complex due to the unique shapes that make up the plan of the building. Most of the structure is reinforced concrete columns and floors. The underground structure of the building is made of 83 Caissons that range is diameter from 36 to 60 inches. Each caisson cap is 40 inches in depth and square with the same width as the diameter of its corresponding caisson. The columns in the building are a mixture of round and rectangular columns. The round columns are 24 inches in diameter and are built with a special, plastic-lined form to produce a smooth finish in any location that they are exposed to view by the occupants. The rectangular columns are either 36”x30” or 34”x16” and are hidden in walls away from the occupant’s vision. The floor system is comprised of a Filigree slab floor and beam system. This system consists of 2-1/4” thick manufactured concrete slabs shipped to field to be assembled, shored, and poured. Slabs include polystyrene foam blocks to reduce floor mass. This method is used in place of traditional cast-in-place construction to speed up the building schedule by reducing the time required for formwork placement. The concrete beams are integrated into the floor system. They range in depth from 10 to 24 inches and width from 23 to 60 inches. Flexural reinforcement in varying sizes is embedded in the beams according to ACI code.

Transfer beams are used to support the walkways that surround the cantilevered walkways around the atrium on each floor. The building has Shear Walls at both the West and South Stairwells as well as around the Elevator Shaft. The elevator shaft includes a unique 30⁰ angle between two walls and another exterior wall connecting them. There is also a set of perpendicular shear walls in the SE portion of the building and another single North to South Shear wall in the East portion. All of the shear walls extend from at or below the basement floor level to at least the finished roof level. Some extend beyond the finish roof because of the stairwell access and elevator equipment rooms at rise to higher points.

The structure at the top of building makes a transition from reinforced concrete to structural steel. On the southeast portion and part of the northeast portion of the building, this transition is just above the 5th floor. On the eastern and northwestern portions of the building, the transition from concrete to steel structure is at the mechanical penthouse level floor. The column sizes for the structural steel framing are either W8x48 or W8x40 depending upon local loads. Cross bracing on selected exterior bays provide lateral bracing.

The 240-seat auditorium located in the northeast corner of the building on the ground floor and extending down to basement level has a structural steel frame that creates the sloped, allowing for a tiered stadium seating arrangement. This frame includes W24x103 girders with W10x26 and W12x26 joists.

The roof structure is one of two assembly types. Over some areas it is rigid foam over a concrete slab with White Carlisle Sure-Weld FB115 Thermoplastic-polyolefin (TPO) membrane. Over the mechanical penthouse on the north and east portions of the building, where there is a steel roof structure, the roof is the same rigid foam insulation and TPO membrane over exterior grade sheathing.