Building Name

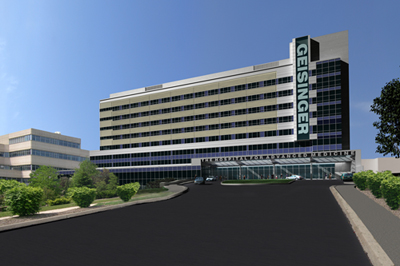

Geisinger Medical Center

Hospital for Advanced Medicine

Location and Site

100 North Academy Avenue

Danville, PA 17822

The site is located in the existing Geisinger Main Campus and is the first step in the Geisinger Master Plan. It will be located on a parking lot which serves the existing hospitals and a parking garage is planned for the future.

Building Occupant Name

Geisinger is a patient-led health care system located in northeastern and central Pennsylvania.

Occupancy

Hospital, including operating rooms, patient rooms, offices, and labs

Size

300,600 sf

Number of stories

9 above ground levels including a mechanical penthouse and one additional lower level.

Primary Project Team

Owner- Geisinger

Architect, Engineer, Interior Design, Healthcare Planning- EwingCole

Civil Engineer- Borton-Lawson Engineering, Inc.

Construction Manager- Torcon, Inc.

Dates of Construction

June 2007- Spring 2010

Cost Information

Total construction cost is estimated at $108,000,000.

Project Delivery Method

Design-bid-build

Architecture

The design of the Geisinger Hospital of Advanced Medicine was centered on the idea of allowing users to get into the building and access medical services as quickly and easily as possible. The main entrance was placed near the future parking garage and large elevators were placed directly adjacent to the hospital. Level one also connects easily to the existing hospital and will be used as a major entrance into the entire hospital complex.

The lower levels of the hospital, lower level 1 through level 6 contain the cardiology, cardiothoracic, vascular, and labs clinic, and operating rooms along with several shell areas which are to be designed later. Levels 7 and 8 are patient rooms and level 9 is the mechanical penthouse.

The building is planning to apply for LEED certification once completed.

Major National Model Codes

International Building Code, 2006

International Mechanical Code, 2006

International Energy Conservation Code, 2006

Life Safety Code, NFPA 101-2000

Zoning

Under the zoning requirements of Danville Borough

Historical Requirements

None

Building Envelope

The main elements of the exterior of the building are precast wall, spandrel glass, glass curtain wall, and a concept wall system of aluminum. The precast wall contains precast concrete panel, rigid insulation, and gypsum wall board. The spandrel glass is glazing, rigid insulation and gypsum wall board. The concept wall system is corrugated aluminum panel, rigid insulation, and an aluminum liner panel.

The roof of the building is mainly concrete deck but also some green roof. The concrete deck contains polysio insulation, normal weight concrete, and metal deck. The green roof is soil, polystyrene insulation, normal weight concrete, and metal deck.

Construction

The hospital is a design-bid-build project. Groundbreaking occurred on June 21, 2007 and estimated completion is in Spring 2010.

Electrical

The service to the Geisinger Main Campus is a 69kV aerial service from PP&L. This power is run to a substation and then split into two separate switchgears, one for the west side of campus and one for the north and east. Power for the hospital will be provided from the north switchgear and run through a new patient pavilion substation.

An emergency diesel generator will be installed for the hospital sized for 72 hours of operation. The generator will provide a 480/277V feeder to the hospital for emergency power.

Lighting

Lighting systems will use T8 lamps, compact fluorescent lamps, electronic ballasts, and occupancy sensors. Lighting voltage is primary 277V. Occupancy sensors will be located in offices, conference rooms, storage rooms, and toilet rooms. Dimming lightings will be located in patient rooms, conference rooms, and radiology rooms.

Mechanical

A new chiller building will be constructed for the campus and house three 900-ton water-cooled centrifugal chillers, two existing relocated chillers and one new chiller. The chilled water pumps will be variable frequency driven. An 8,000 ton-hour, thermal energy storage tank will also be housed in the new chiller plant.

An addition to the existing boiler house will be constructed. Two new steam boilers will be installed here, one gas powered, low NOx boiler and one electric boiler/

The ninth floor penthouse will house four 80,000 cfm air-handling units, three to be installed now and one in the future. The air handling units will be manifolded into two groupings of two units each, one group for the north side of the building, and the other for the south. There will be two additional 18,000 cfm air handling units located in the fourth floor mechanical room, one installed now and one in the future, these air-handling units will supply the operating rooms on the second floor.

The hospital will use a variable air volume distribution system with VAV boxes and hydronic reheat coils. Spaces with positive pressure requirements will use both supply and return boxes. All supply, return, and exhaust air will be installed with exterior installation. All high occupancy spaces will have CO2 sensors installed in their return air ductwork. Supply air will be distributed through ceiling diffusers.

Structural

The hospital will be supported by a deep foundation system using micropiles. This was chosen due to the soil conditions and the need to limit vibration during construction to adjacent hospitals. The ground floor will be slab on grade. All other floors will be concrete on metal deck with thicknesses varying according to the intended use of the spaces. Floor framing consists of structural steel wude flange beams and girders. Columns are spaced at 30 feet in one direction and vary from 15 to 32 feet in the opposing direction. The maximum beam spacing is 10 feet. The lateral system consists of steel concentrically braced frames in both directions

Fire Protection

The campus utilizes a Simplex fire alarm system. A new Simplex 4100 series system will be provided for the hospital and connected to the existing system. The fire alarm system will include smoke detectors, sprinkler system interfaces, and manual pull stations.

|