General Building Statistics

Building Name: Peirce Hall

Location: Gambier, Ohio

Building Occupant(s): Faculty and students of Kenyon College

Occupancy types: A-2 (restaurant) and A-3 (assembly)

Construction type: IIB

Size: 66,640 SF

Stories/Levels Above Grade: 5

Project Team:

Owner - Kenyon College http://www.kenyon.edu/index.xml

Architect - Gund Partnership http://www.gundpartnership.com/

Structural Engineer - LeMessurier Consultants, Inc. http://www.lemessurier.com/

Construction Management - The Albert M. Higley Co. http://www.amhigley.com/

Mechanical, Electrical, and Plumbing Engineers - Syska Hennessy Group http://syska.com/

Dates of Construction: Spring 2006 - Spring 2008

Total Cost: $18 Million

Project Delivery: Design-Bid-Build

Architecture

Governing Codes:

International Building Code, 2003 Edition

Ohio State Building Code, 2005 Edition (a modified version of the 2003 IBC)

International Mechanical Code, 2000 Edition

International Fire Code, 2000 Edition

International Plumbing Code, 2001 Edition

Ohio State Plumbing Code, 2003 Edition

BOCA Building Code, 1998 Edition

National Fire Protection Association

Located at 201 College-Park Street on the Kenyon College campus in Gambier, Ohio, Peirce Hall is one of the college's signature buildings. Peirce Hall is predominantly used as a dining facility, but also contains office, conference, and lounge spaces. This classifies the hall as a mixed use building.

Kenyon College was founded in 1824 and prides itself for being the oldest private college in Ohio. As such, the college and the town of Gambier, Ohio try to protect the original campus architecture and atmosphere as much as possible. Much of the Kenyon College campus is classified by the "Zoning Ordinance of the Village of Gambier, Ohio 2003," as historic institutional district. Although the Peirce Hall falls just barely on the other side of this districts border and is considered part of the institutional district relieving any historical requirements. Regardless of this fact the addition to Peirce Hall was designed to match the original structure and its gothic appeal with the addition of a few modern ideas. Similar materials such as the sandstone veneer, limestone trim, and bluestone treads were used in the facade and walkways. The same graduated slate roof, copper gutters, and steel windows were also continued around the facade.

Not many zoning requirements had significant impact on the new design, due to the open nature of the site. Additional information on the zoning regulations of Gambier, Ohio can be found at http://www.villageofgambier.org/.

|

Building Enclosure

The facade of the original Peirce Hall was mirrored in the new construction. Three exterior wall types were used, composed of the following materials:

Type 1: Type 3: |

|

Fenestration in the addition was designed to be consistent with the original building's steel windows. However, large aluminum framed curtain walls were also added allowing more natural daylight in to the massive structure. There is also a sloped class roof over the central servery link and one large skylight in the southern servery. Two types of insulating glass manufactured by Viracon were specified; one for exterior glazing and the other for skylights. Characteristics for the two types are as follows:

Exterior Construction: Visible Light Transmittance: 70 percent Skylight Construction: |

|

Visible Light Transmittance: 19 percent

Reflectance Visible Light: 26 percent

U Value (Winter): 0.31

Shading Coefficient: 0.21

Solar Heat Gain Coefficient: 0.18

Four types of roofing are used in Peirce Hall. The first two types are for the areas of the building that are above grade. The second two roofing types provide adequate protection to the portions of the building that have roofs which meet grade. The types are constructed in the following manner:

Type 1: |

|

Type 2:

Modified bitumen roofing

Protection board

Tapered rigid insulation, 3" min. slope 1/4" per foot

Continuous air & vapor barrier membrane

Roof slab on metal roof deck

Type 3: Type 4: |

|

Sustainability Features

The majority of sustainable features in the new Peirce Hall can be found by observing the mechanical system installed. The mechanical system includes the following features:

-

All air handler's fans, chilled water and hot water pumps have variable frequency drive motors allowing for adjustable control without wasting energy

-

Motors that are scheduled to run for more than 2000 hours per year are premium or high efficiency motors.

-

Air handling units are equipped with air side economizers.

-

The building automation system (BAS) is programmed with schedules to maximize energy savings such as night setback, optimum start controls, and peak load management.

Part II

Primary Engineering Systems

Construction & Planning

Contracts for The Peirce Hall renovation, addition, and expansion project were determined through a design-bid-build process. Once the bidding process was complete and contracts were signed, it was decided that structural consultants LeMessurier Consultants, Inc., MEP/FP consultants Syska Hennessy Group, and construction managers Albert M. Higley Co. would be the primary project team.

|

| [+] Click on image to enlarge |

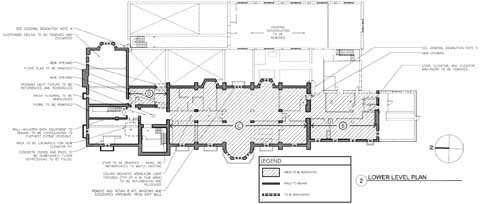

The initial stage of the project involved the demolition of portions of the building to the East and South of the original Great Hall and servery, tower, and multi-story sections. These areas can be seen in the following image. In addition to structural demolition, Peirce Hall was gutted of most existing mechanical and electrical systems. New structural, architectural, mechanical, electrical, plumbing, and fire protection systems were then installed. The total renovation cost amounted to $18 million

Structural

The newly erected structural system supporting Peirce Hall primarily utilizes a non-self-supporting steel gravity system. As a non-self-supporting system, steel frames require the interaction of the floor and roof deck diaphragms to provide the required stability and resistance to wind and seismic forces. Lateral support is provided by moment frames, diagonal hollow structural steel braced frames, and shear walls around elevator and stair shafts. Steel wide flange members range from W6x20 to W30x90, but are typically between W6x25 and W12x26 and span up to 43 feet. Roof structural support predominantly comes from steel deck on W18x35 and W10x12 steel beams. Floor types the first floor and above are composed of a 5 1/2" to 7 1/2" total thickness composite deck construction with 3 1/2" light weight or 4 1/2" normal weight, 6x6-W2.0xW2.0 welded wire fabric reinforced concrete. All levels with direct contact to the ground have a 6” to 8” slab on grade. Foundation walls and piers support columns and the floors above. All concrete used in footings, foundation walls, and slab on grades use 4000 psi concrete, where normal weight concrete on steel deck, topping slabs, and housekeeping pads are 3000 psi.

|

Mechanical

The original Peirce Hall was supplied steam from the campus system, but did not house any type of chiller plant. As a result, the new chilled water plant required all of the equipment that was to be held in this room to be able to fit through a 3’ wide entrance. The primary cooling system uses a modular chiller with two 25 ton scroll compressors. Condenser water is circulated for the entirety of the year through a cross flow type, axial fan driven cooling tower, located on the roof. All pumps involved in the chilled water system are controlled by a variable frequency drive. Chilled water is supplied to 6 of the 7 air handler units that provide ventilation to spaces in Peirce Hall.

|

The primary heating system utilizes the medium pressure (26 psi) supplied by the campus central steam system. Steam is supplied directly to air handlers, unit heaters, and steam converters. A few existing steam converters were upgraded for reuse and currently supply hot water to hydronic perimeter baseboards and the radiant floor system in new dining rooms. Existing radiation units in Peirce Hall were reused and refurbished as necessary.

Electrical

Service power to Peirce Hall is received by a 1000kVA, 12.47kV/208V pad mounded transformer with 208/120V main switchgear. Service voltage is 208Y/120V, 3 phase, and 4 wire with a 3000A, 208Y/120V main switchboard. The ampacity of the service has been sized to support up to 30 VA per square foor of peak demand. A 400A, 100kW/125kVA, 208/120V natural gas fueled generator has been provided to satisfy emergency needs of the building refrigeration system. Panelboards, cables, and circuit breakers have been sized to satisfy design loads with a future allowance of 20% load growth and branch circuit panelboards have been equipped with 20% spare circuit breakers.

Lighting

In the new lighting design of Peirce Hall, new lighting fixtures were provided throughout the facility. Attempts to limit the number of types of lamps used were made to reduce maintenance inventory. Common lamp types used are T8 linear lamps and 13W, 26W, and 42W compact fluorescents. 120V lighting fixtures were used in the design with fluorescent lamps rated at 3500°K and a minimum color rendering index of 80. All lighting loads are fed from relay light panelboards equipped with an integrated programmable logic controller which can act as a time clock. Emergency lighting fixtures are equipped with a “Bodine” style battery, rated for a 90 minute operation period.

|

Fire Protection

Wet and dry stand pipe systems we installed where necessary during the Peirce Hall project. The standpipe system was designed to conform to the Ohio Fire Code and NFPA 14 requirements. The main pump is capable of providing 750 gpm at 75 psi and 60 HP. Flow through the branches of the system is monitored with control valves and water flow switches in addition to a system drain/test connection. As a sprinklered building, Peirce Hall qualifies a building construction Type IIB construction for new construction, unprotected combustible/noncombustible.

Vertical Transportation

Three hydraulic elevators are used for vertical transportation. Elevator 1 is a 2500 lb capacity holed, single door, 5’-9” x 8’4” elevator that services the tower portion of Peirce Hall. Elevator 2 is a 3500 lb capacity holed, double door, 7’-8 1/4” x 8’-4” elevator that provides public service to the lower level and first floor. Elevator 3 is a custom 9000 lb capacity holed, single door, 9’-4” x 12’-10” elevator that services the basement, lower level, and first floor.

Telecommunication

Various types of telecommunication cabling are used in Peirce Hall. For use as horizontal cable, Category 6 UTP and 4-UTP is used. 50-pair 24AWG UTP CMP copper cable is used for backbone applications.