PENNSYLVANIA COLLEGE OF TECHNOLOGY DAUPHIN HALL Williamsport, PA |

AUBERT NDJOLBA |

STRUCTURAL OPTION |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

BUILDING STATISTICS

|

ARCHITECTURE

The exterior of this new dormitory was constructed almost entirely of four (4”) inches split-face block with horizontal reinforcement at 16” on center vertically and with 6” block with horizontal reinforcement at 16” O.C. on the inside, and an additional 4” rigid insulation in between. The windows are fixed prefinished aluminum units with insulated glass. The curtain walls are made of prefinished aluminum horizontal and vertical mullion with 1” insulated tempered safety glass.

South facade

CONSTRUCTION

This new structure costs approximately $ 26,000,000 and was delivered using the design-bid-build project delivery method.

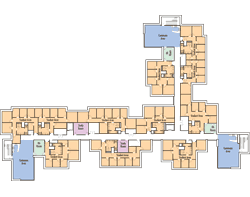

At approximately 123,676 GSF, this latest addition to the student housing, provides 268 students with suites and single rooms. A 40-50 student seating commons enclosed with glass provides a social space for student collaboration. Located within the dormitory are other amenities such as: a 460 seat dining room, two private dining rooms for faculties, a 40 station satellite fitness center, two large leisure rooms, a student grocery store, laundry facilities, student mail boxes, Resident Life Offices, campus police office, and a Hall Coordinator apartment.

First Floor Plan .........................................................Upper Floor Plan

ROOFING

The roofing system used in this case was composed of architectural fiberglass shingles, 30# asphalt impregnated building felt, ¾” TH. Fire-retardant plywood sheathing, supported but light-gauge pre-engineered roof trusses @ 2’-0” O.C. The whole system is covered with continuous BATT insulation with vapor barrier at the bottom of roof trusses.

SUSTAINABILITY FEATURES

Even though the Dauphin Hall (DH) does not have LEED silver or gold rating, it contains green features such as efficient lighting, bike racks, low water consumption equipment, natural lighting provided by curtain wall on the North-Western side of the building, and recycling bins on all hallways of every floor.

STRUCTURAL SYSTEMS

The floor system of the DH is composed of 4” Light weight concrete slab, reinforced with 6”×6” –W2.9×W2.9 welded wire mesh, on 1 ½” - 20 gage Vulcraft composite deck. The joists, supporting the floor system, are spaced equally in column bays with a maximum spacing of 2’-0” O.C in areas of floor framing.

The superstructure of the DH is primarily a combination of K-series joists, W24 girders, steel columns raging in size from W8’s to W10’s, and light gage metal framing. The K-series joists are spaced 2’-0” on O.C. The columns are typically on a 25’x30’ grid and encased by 5/8” Gypsum board or 6” painted CMU. HSS columns were used in locations near the stairwells. Interior partitions consist of non load bearing Concrete Masonry Units (CMU).

The lateral resisting system in the DH consists of steel moment frames in both the East-West direction and the North-South direction.

MEP SYSTEMS

Through the use of a constant volume single-zone HVAC unit, the mechanical system of the Dauphin Hall uses Variable Air Volume (VAV) to provide temperature control of multiple comfort zones. In addition, it uses ceiling mounted voltage occupancy sensors with emergency standby generators; fluorescent, Metal-halide and LED lights; and a wet pipe sprinkler system.

| Note: While great efforts have been taken to provide accurate and complete information on the pages of CPEP, please be aware that the information contained herewith is considered a work‐inprogress for this thesis project. Modifications and changes related to the original building designs and construction methodologies for this senior thesis project are solely the interpretation of Aubert Ndjolba. Changes and discrepancies in no way imply that the original design contained errors or was flawed. Differing assumptions, code references, requirements, and methodologies have been incorporated into this thesis project; therefore, investigation results may vary from the original design. |