Building Statistics II

The Mueller Laboratory building on the Penn State University Park campus was built in 1963. It was not until fifteen years after its construction that it was actually given its current title, named after Erwin W. Mueller. Erwin Mueller, a Penn State faculty member from 1952-1977, was the first person to experimentally observe atoms, and developed several high precision microscopes to study atoms.

Even though the Mueller building shares its name with such a brilliant scientist, the building itself is rather low-tech. In the 51 years since it was built the laboratory has not undergone a significant renovation. Notably, in 2001 Penn State professor of ecology Christopher Uhl led a team of grad students in studying the sustainability shortcomings of the Mueller building. The team released a 56 page document, titled "The Mueller Report," detailing numerous failings of the building. The report also contained investigations of possible improvements, detailing both their environmental impact and their financial cost and feasibility.

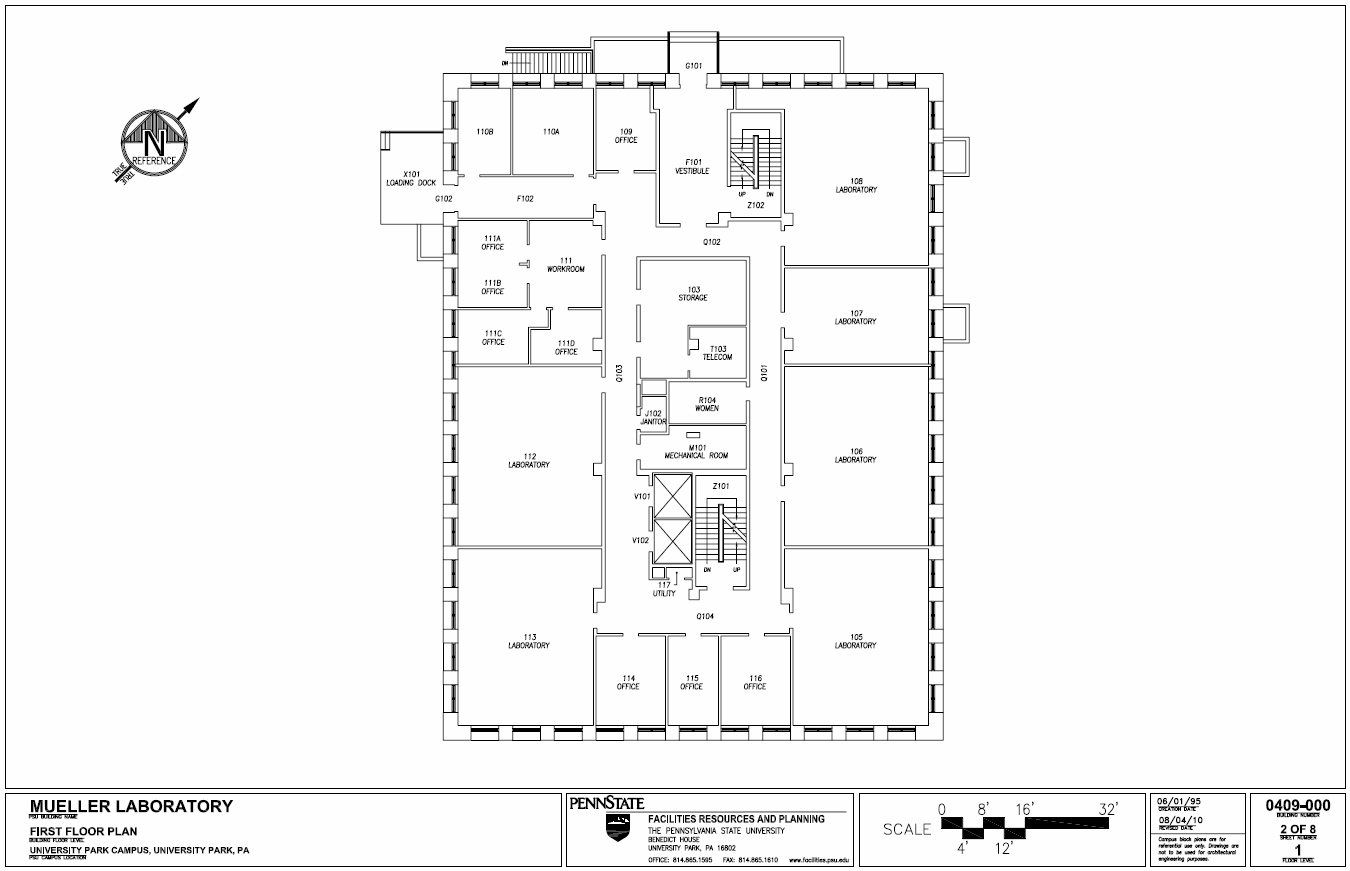

Finally, in 2013, Penn State chose to begin the renovation of the Mueller building. Robert Bloom, Facilities Project Manager for Penn State's Office of Physical Plant was chosen as project leader. Priorities included full renovation of labs on 4 (four) of the building's 7(seven) floors, overhaul the laboratory exhaust system, replace the outdated mechanical and electrical systems, and install a new fire sprinkler system. All applicable codes, still being researched by the author, will be followed on the Mueller renovation, as with any Penn State project. Overall 75,482 square feet of the building would be renovated. Although much of the interior of the building would be gutted, the building's facade would not change extensively during the renovation. This meant that matching surrounding buildings and the entire Penn State campus was not a concern, since essentially the only outwardly visible change would be new, more efficient windows. Stantec, which has a State College office, was chosen to do the design drawings.

Penn State collected bids for the project in fall of 2013. Barton Malow was selected as the CM firm, with a team led by Scott Mull. Starting in May of 2014, the renovation is schedule to be completed in August of 2015, in time for the start of that year's fall semester. By its completion roughly 18 million dollars will have been spent on the renovation.

Many pieces of the building's renovation will make it more sustainable and reduce its impact on the environment. The windows are being replaced with energy efficient glazing. Connecting to campus chilled water will benefit from the economy of scale, saving energy. Improved ventilation systems will both be more efficient and provides safer laboratory environments. And improved electrical distribution will minimize loses. Specific details of products being installed is being researched by the author at this time.

Though not an architectural marvel, once completed the renovated Mueller Laboratory will hopefully set an example to other labs across the university and even the nation as one of sustainability and energy efficiency. Techniques used to bring the building into the modern era can be applied to many similar structures. Penn State shows itself at the forefront of sustainability with its renovation of Mueller Laboratory.

Construction

A large portion of the project involves selective demolition of existing systems. Care is to be taken to not disrupt HVAC, electrical, or data service to areas of the building that are not being renovated and remain occupied.

Electrical

Power runs into the building from Penn State's 12.47KV loop through two 1600 Amp switchboards. Individual bus ducts are run to each floor of the building. 208 volt 4-wire 3 phase panel boards feeds power to lighting and outlets. All new lighting in the building is to be LEDs, most with occupancy sensors and dimming functions, wired at 208 volts.

Mechanical

Three air water air handler units, with provision to later add a fourth, are placed on the roof to provide heating and cooling to the building. Propylene glycol is used as the heat transfer fluid, as is required for food-grad spaces, such as the biology labs. Four 25,000CFM exhaust fans reside on the roof to provide exhaust for the lab spaces. Supply and return air ducts run vertically at the corners of the building. Exhaust ducts run vertically on the north face of the building.

Structural

The duct enclosures are framed by hollow structural steel (HSS) ranging from 2x2x1/4 to as large as 8x4x5/16, welded together at the connections. An L3x3x1/4 is used as a brick shelf, set every 12'6 along the structure's height. The steel structure rests on 8 and 13 inch concrete walls set on 12"x25" 2000psf concrete footings.

Fire Protection

All floors of the building receive new smoke alarms tied into the new initiation circuit. The elevator is also tied into the new fire alarm control panel and programed to react appropriately in emergencies.