Alkali Silica Reaction

Concrete Pipe Collapse (Haavik, Douglas J. and Mielenz, Richard C. , 1991)

A 2 year old, 36 inch diameter, 5 inch thick, buried, standard-reinforced-concrete pipe failed because of ASR. The pipe, manufactured with river aggregate and Type II low-alkali cement, was used to convey acidic, alkaline, phosphatic, sulfate, and heated (up to 180 ° F) brines that were used to flush a power generation plant’s piping system to a storage pond. (See Figures 1 and 2)

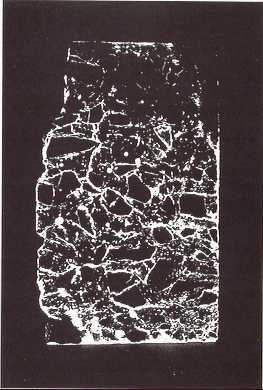

Figure 2 : Pipe detail. (Haavik and Mielenz, 1991, p. 55)

After the collapse, the top of the pipe was uncovered for inspection. Cracks, ranging from hairline cracks to 1/8 inch cracks, existed lengthwise on the pipe’s crown. In the center section of pipe, several areas separated from the structure and dropped into the pipe. Generally, the breaks occurred along rebar sections however no rebar corrosion was apparent.

Examination of the pipe showed damage equivalent to a 30 year life. A petrographic examination revealed an intense chemical attack on a cryptocrystalline ground mass causing radial cracking throughout the surrounding concrete matrix. In these cracks an abundant amount of alkali-silica gel was found. Also, particles of quartzite, quartz, chalcedonic cherts, and rhyolite were found to be affected by ASR.

The cause of the failures was determined to be the brines conveyed. The temperature of the substance accelerated the ASR process.

The Matilija Dam, Ventura County, CA (ENR, select references)

The 163 feet high, concrete arch Matilija Dam in Ventura County, CA was 16 years old when a routine inspection diagnosed the dam as "suffering from internal swelling, exterior cracking, and general disintegration" in the top 30 feet of concrete. In addition to the concrete distress, the abutments were moving as well.

The owner of the dam acquired the services of Bechtel to evaluate the structure after the initial diagnosis. They recommended that the behavior of the dam be studied over several years however the dam's liability insurer demanded immediate action in order to maintain the policy. As a result, the owner elected to drain the dam, open all relief valves, and pursue a study of the facility.

Bechtel proceeded to observe the dam’s behavior through filling and drawdown cycles of the reservoir. They also cut core samples from the concrete arch for petrographic and strength testing. Their analysis discovered that the dam’s safety factor was below the accepted minimum and there was severe expansion and cracking in the upper 20 to 30 feet of the dam which they attributed to ASR. Their final recommendation was to remove a 280 feet by 30 feet notch from the dam breast to reduce the pressure on the structure so that it could provide service for another 15 years under a regular monitoring scheme.

As a result, the level maintained in the reservoir was maintained below the affected concrete and subsequent monitoring found the facility to be safe.

Charles Cross Car Park (Hobbs, 1988)

Tests administered on a core taken from the beam shown in Figure 3 are summarized in the Table 1 along with the compatibility of each observation with ASR. As you will see, this analysis concludes that ASR is the problem in the car park.

Observation |

Is the observation compatible with ASR cracking? |

|

| Structural cracking | Cracking characteristic of ASR. See Figure 3. | Yes |

| Depth of macrocracks | 24-45 mm, approximately 1/10th of the section thickness | Yes |

| Crack distribution under UV light | Extensive microcracking, expansion has occurred. See Figure 4. | Yes |

| Crack distribution in thin section | Extensive microcracking, expansion has occurred. | Yes |

| Thin section examination for gel | Isotropic gel, gel filled microcracks, gel saturated paste | Yes |

| Reactive silica | In sand fraction | Yes |

| Cement content | » 530 kg/m3 | Yes |

| Solubilized silica content from aggregate | --- | |

| Estimated original alkali content | 5.6 - 7.2 kg/m3 | Yes |

Table 1: Charles Cross car park test data.

Figure 4: Internal microcracking illuminated with UV light. (Hobbs, 1988, p. 101)