Concrete Early Strength

The reduction of w/cm by 20 to 25 % enhances concrete early strength by 50 to 75 % as shown in figure below:

Figure 1 Influence of the addition of superplasticizers on the early strength of concrete with cement content of 370 kg/m3 and cast in room temperature (Neville, 1995).

Loss of Workability

Figure 2 Loss of Slump

with time of Concrete: (A) w/cm 0.58 and no admixture; (B) w/cm 0.47 and

superplasticizers (Neville, 1995).

Figure 2 Loss of Slump

with time of Concrete: (A) w/cm 0.58 and no admixture; (B) w/cm 0.47 and

superplasticizers (Neville, 1995).Careful use of superplasticizers is very important because of its relatively short effect on concrete workability. Rapid slump loss which results in loss of workability will occur 45 minutes after the introduction of superplasticizers. The rapid slump loss, compared with concrete without superplasticizers, is shown in figure 2 above. An example of melamine based superplasticizers is Melmet (produced by WR Grace Admixture). The dosage rate ranges from 6 – 25 oz. for every 100-lb of cement. The lower dosage will provide the Type A (Water Reducing) and mid to high dosage will provide Type F. Current product of superplasticizers has an extended slump retention time twice than the conventional one (up to two hours). Examples for these are Daracem-100 (WR Grace Admixture), Rheobuild (produced Master Builders Technologies).

Another slump retention effort is through re-dosing superplasticizers to the concrete mix. Figure 3 below shows repeated re-dosage of naphthalene based superplasticizers to regain slump. Re-dosing practice should be explored with trial mix with close similarity of field condition as rapid slump loss occurrence is detected. Other disadvantages of re-dosing are possibility of bleeding and segregation, or air entrainment in the mixture.

Compatibility of Portland Cement and Superplasticizers

The fixing between C3A of Portland Cement and superplasticizers will result in loss of workability. This process occurs if the calcium sulfate is not liberated fast enough to react with C3A.

Factors accountable to the compatibility between superplasticizers and cement are C3A and C4AF content in the cement, reactivity of C3A, calcium sulfate content, final form of calcium sulfate in ground cement (hemihydrite, dihydrite, or anhydrite gypsum), molecular chain length of the superplasticizers, position of the sulfonate group in the chain, the counter-ion type (sodium or calcium), the presence of residual sulfates which affects the de-flocculation properties. Based upon these factors, Neville proposed ideal cement properties for high performance concrete as fineness up 400 m2/kg determined by Blaine method and low C3A content.

Incompatibility of cement and superplasticizers can be a result of cement reactivity or poor performance of superplasticizers. Cross testing can be performed to evaluate the problem by applying other admixtures and other cement. Incompatibility can be reduced by adding retarding agent or pozzolanic material (Aitcin, 1994).

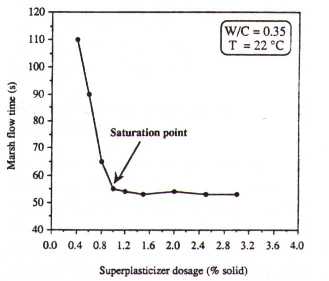

Effectiveness of superplasticizers is measured by the time taken by a fixed quantity of cement paste and particular content of superplasticizers to flow through a standard funnel, known as Marsh flow cone (Figure 4). Recommended optimal dosage is not to exceed the saturation point from the Marsh Flow Test (Figure 5). Excessive dosage (beyond saturation) may lead to segregation problem.