|  |

The Saugus Iron Works, in Saugus, Mass. (about 20 miles north of Boston) | Braintree Furnace, Saugus, Mass. |

Saugus Iron Works

The Furnace

To the right, a view from the charging bridge today, looking down on the waterwheel of the furnace, and with a view of the waterwheels of the forge in the distance.

Here two views of the furnace's tapping arch, where the molten iron was tapped from the furnace onto the hearth. At left is a view of the arch today and to the right in a diorama as it would have appeared back when the hearth was functioning.

The Saugus furnace worked like all medieval and early modern furnaces - loads of iron ore, charcoal, and often a calcium-based flux (crushed limestone or oyster shells were common) were alternately poured in the top of the stack. As the charcoal burned, urged on on by the bellows (the modern frame of which is being rebuilt at right), the furnace temperature rose to over 1400°C and the iron melted and flowed to the bottom.

To the right, you can see the giant axle of the waterwheel whose cams (the small wooden protrusion seen here on top) rotated around massaging the back end of the bellows. The cam arrangement can also be seen driving the massive triphammers in the forge, on the following page: saugusIW1.html.

To the right, you can see the giant axle of the waterwheel whose cams (the small wooden protrusion seen here on top) rotated around massaging the back end of the bellows. The cam arrangement can also be seen driving the massive triphammers in the forge, on the following page: saugusIW1.html.

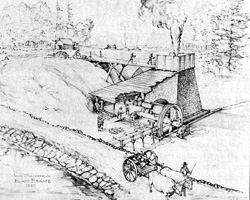

The Forge

The Forge, like the Furnace, was powered with waterwheels. In this case, there were four - two per side, that powered bellows and large triphammers inside the building.

Closeups of the Forge's Waterwheels

Here are a number of pictures of the four waterwheels that power the forge. The two overshot wheels at right power the bellows that pump air into the hearths, allowing the pig iron from the furnace to be reheated for hammering.

These two images (left and center) are of the waterwheels that power the triphammers. Notice that even though they power similar hammers inside the building, they are of completely different design. The uphill (rear) one is a typical overshot wheel where water falls from the sluice above, over the top of the wheel, turning it clockwise (when viewed from the end). In the center image, you can see a close-up of the lower wheel, which is of undershot type. Water runs down the chute from the sluice and the extended paddles of the wheel are pushed by its velocity rather than weight (as with the overshot), turning the wheel counterclockwise (again, viewed from the en). Both methods are sufficient to accomplish the same goal of turning the camshafts for the triphammers.

The reason the Saugus builders used different methods is that inside the building, the two forges and anvils are set in mirror-image fashion, so for the triphammers, the two camshafts need to turn in alternate directions. For the bellows on the Forge hearths, the two shafts from the overshot wheels also need to turn in opposite directions, but as you can see from the photo on the right, this is accomplished by having the water fall over one wheel from the uphill side and the other from the downhill side. If nothing else, these multiple solutions to simple problems show the ingenuity of Colonial millwrights.

The Triphammer and Cams

At left you can see the original hammerhead (on a modern wooden shaft) in the museum. The head, which weighs 550lbs., was recovered in the archaeological excavations on the site in the 1950s.

Center and right, closeups of the cams (on the bellows at the Furnace, above, and the bellows in the Forge, right), showing how as the camshafts rotate and press down on on the tail of the bellows, pumping them typically twice per revolution.

The Rolling Mill

Once the Furnace had made its pig iron, and the Forge had 'fined' it into wrought iron, it was forged into bars and then ready to be sent to blacksmiths for whatever purpose they needed.

The owners of the Saugus Iron Works, however, also saw a profitable market in making nails and consequently built a Rolling and Slitting Mill to turn the bar iron into small iron strips suitable for individual sail or which could be made into nails with very little effort by any local blacksmith.

Return to:

One-Minute Essays

|

||||||||||

|

||||||||||