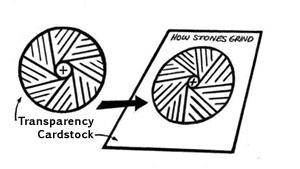

- Students will create a model that demonstrates how stones grind.

- Students will compare millstone patterns to identify how the grain is turned into flour as it runs from the central hopper to the perimeter.

How Millstones Grind

Robert P. Rich and Steven A. Walton

Learning Objectives

Background

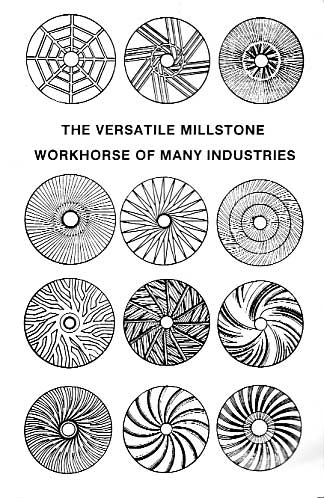

In order for a millstone to cut the grain into flour - for that

is exactly how grain is ground - the millstone faces need to

have grooves cut into them. The pattern of these grooves

varied from stone to stone and from region to region, and stone

dressers developed both elaborate and subtle variations for different

grains, different grinds (much like the range of grinds of coffee

available today), and different grain conditions. The patterns

on the stones working together act like a pair of scissors to

cut the grain as the stones rotate.

In order for a millstone to cut the grain into flour - for that

is exactly how grain is ground - the millstone faces need to

have grooves cut into them. The pattern of these grooves

varied from stone to stone and from region to region, and stone

dressers developed both elaborate and subtle variations for different

grains, different grinds (much like the range of grinds of coffee

available today), and different grain conditions. The patterns

on the stones working together act like a pair of scissors to

cut the grain as the stones rotate.

When we speak of a grindstone, we can either

mean each of the pair or the two together, for you must have

a pair to do any useful grinding. The bottom stone is called

the bedstone and it remains stationary - in fact, it is set into a bed of

concrete or mortar to make it literally rock stable. The top, rotating stone

is called the runner stone, and it has a hole in the middle through which

the grain is fed. Both stones have a pattern of grooves cut into their working

faces (top face for the bedstone and bottom face for the runner stone) that

act as feed channels for the flow of the grain to the outside edge. As the

two stones rotate against one another - never touching! - the

grain is repeatedly scissored between the grooves, whose gap varies from

well less than 1/8" near

the center down to thousandths of an inch at the perimeter. Individual grains

are cut again and again on their journey from the center out to the edge.

A stone dresser would come to the mill once a year and re-face the stones

to keep the grooves crisp and the stones milling smoothly through the year.

For more information on the patterns in millstones, see Jon A. Sass, The

Versatile Millstone: Workhorse of Many Industries (SPOOM, 199), available

directly from SPOOM.

For more information on the patterns in millstones, see Jon A. Sass, The

Versatile Millstone: Workhorse of Many Industries (SPOOM, 199), available

directly from SPOOM.

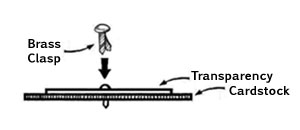

Materials

For each model of a millstone pattern, you will need the following:

Instructions

Questions

Return to:

Educational Projects

|

||||||

|