|

SALK HALL LABORATORY

Located at the University of Pittsburgh Main Campus

Christopher Kelly

Architectural Engineering

Mechanical Option |

|

This page was last updated on October 11th, 2010, by Christopher Kelly and is hosted by the Department of Architectural Engineering at the Pennsylvania State University. |

|

University of Pittsburgh Salk Hall Addition

Nature of the Project:

The total scope for this project consists of the construction of a new research tower of approximately 81,116 gross square feet connected to Salk Hall (see I1). The project will create the much needed additional research laboratories and related ancillary spaces for the Schools of Dental Medicine, Pharmacy, and the Graduate School of Public Health (GSPH).

The project scope also includes renovations, upgrades, extensions, expansions and/or replacement of the following systems: HVAC, electrical, fire protection, water, waste, telecommunications, data, security, controls, and laboratory specialty systems in Salk Hall and the Salk Hall Annex as required to accommodate the new Salk Hall Addition. The underlining goal is to improve system function and energy efficiency, meet applicable Codes, and accommodate upgrades and the expansion of the buildings’ research, teaching, administrative, and auxiliary facilities. |

|

Building Information:

Name: Salk Hall Location: Pittsburgh, PA Owner: University of Pittsburgh Dates of Construction: November 2010-April 2012 Project Delivery Method: Design-Bid-Build Actual Cost Information: $42,095,739

Project Team:

Architecture & Engineering - Ballinger http://www.ballinger-ae.com/

Associate Architect - DRS Architects, Inc. http://www.drsarchitects.com/ Existing Salk Hall (I1)

Lab Planners - Jacobs Consultancy- GPR Laboratory Planning Practice http://www.jacobsconsultancy.com/

Civil Engineers - Raudenbush Engineering, Inc. http://www.raudeng.com/

Landscape Architects - Klavon Design Associates, Inc. http://www.klavondesign.com/

Structural Engineers - Hope Furrer Associates, Inc. http://www.hfurrer.com/

Door & Hardware Consultant - Jack Soeffing Company No website available

Elevator Consultants - Van Deusen & Associates http://www.vdassoc.com/

Specifications Consultants - Conspectus, Inc. http://www.conspectusinc.com/ |

|

Monday, May 02, 2011 |

|

Applicable Codes:

The Building Code of The City of Pittsburgh 2006 The Mechanical Code of The City of Pittsburgh 2006 The Plumbing Code of the Allegheny County Health Department 2006 The Fuel Gas Code of the City of Pittsburgh 2006 Electric Code Administrative provisions of The City of Pittsburgh 2006

Analysis of the International Building Code 2006 Applicability:

Chapter #3: Use and Occupancy Classification Classification of occupancy: B (Business) Use Group Classification of occupancy: A-3 (Assembly) Use Group (First Floor Lobby)

Chapter #4: Special Detailed Requirements Based on Use and Occupancy Hazardous materials shall be limited by tables 307.1(1) & 307.1(2) Controls shall be per table 414.2.2

Chapter #5: General Building Heights and Areas Grade Plane established at 1090.75' Building Height: Building Area: 81,116 SF |

|

Summary of Architectural Plan:

The new addition to Salk Hall will be located on campus just north of the existing Salk Hall complex, occupying what is currently a surface parking lot and a heavily wooded, steeply sloped site between Darragh Street and Sutherland Drive. The new building will physically connect to the existing building (see R1) in selected locations while reinforcing pedestrian access east and west across the site, between the buildings. The program will be accommodated on five floors above grade with a partial penthouse. Floors two through five will contain research laboratories. Floor one will contain some conference space and an additional mechanical area.

|

|

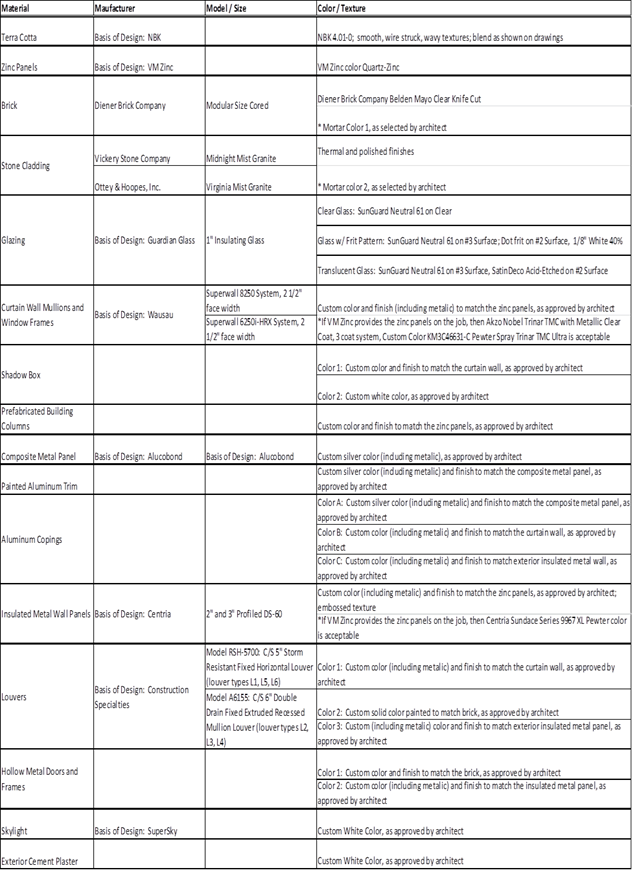

The exterior skin of the building will be a combination of a terra cotta rain screen, zinc panel cladding, glass, and brick in light tones. Face brick will be standard modular, running bond, brick buff colored and wire cut. The roofing system will consist of a white, single ply adhered membrane over rigid polyisocyanurate insulation board mechanically attached to the structure. The curtain wall will be a semi-custom aluminum system with full thermal break including custom mullion covers.

There are no special zoning or historical requirements.

Building Enclosure: See table below |

|

Aerial View of Salk Hall w/ Addition (R1) |

|

Sustainability Features:

The Salk Hall Addition was designed with the intent to pursue a LEED certification; the contract documents however specify that no specific rating must be met. Being that the project was temporarily placed on hold, an original occupancy date of summer 2011 was planned, sustainable design criteria may have received secondary attention due to monetary concerns.

Construction documents were delivered to the owner August of 2010 and a LEED consultant is expected to join the project team to review the original plan. The main areas of focus from the original sustainable design template were to reduce interior water consumption substantially, reduce interior process lighting as much as possible, and to maintain a steady state ambient temperature and humidity level within the laboratories. The glass curtain wall (see R2) allows for exceptional day-lighting within the offices. |

|

Laboratories often struggle meeting LEED EA Criteria due to the massive amount of air that has to be circulated through the wet & dry lab spaces for safety reasons. The HVAC system is 100% OA with moderate- to- high air change rates in the lab spaces. All labs include fume hoods as well. This fact alone is detrimental for laboratories when it comes to EA Credit 1: Optimal Energy Performance. The fan power allowance for a baseline building that ASHRAE Standard 90.1_2007 stipulates often is the main performance characteristic that limits energy savings. |

|

Arrival/Main Entrance (R2) |

|

[All Images and Renderings are the property of Ballinger] |

|

Structural System:

The structural frame for the new Salk Hall Addition will consist of a structural steel frame supported by a foundation of spread footings and deep foundations. Because the building is situated over an existing mine cavity, grout infill of the cavity will be required prior to placing the footings. The typical floor construction will consist of concrete on composite metal deck supported by filler beams and girders. Maximum beam and girder depths are 24”. The Mechanical level will be similar with additional members, as required, to support the proposed equipment. All roof levels will consist of a metal roof deck supported by filler beams and girders. Columns will be W10 or W12 members. A pedestrian bridge will connect the 2nd Floor of the Addition with the 5th Floor of the existing Salk Hall. The bridge will be steel framed with girders spanning between buildings at the floor and roof levels. |

|

Civil Engineering Details:

The site for the proposed Salk Hall Addition is located on the University of Pittsburgh Main Campus and is situated within the 4th Ward of the City of Pittsburgh, Pennsylvania. The proposed project area is currently under the conditions of an existing asphalt pavement parking lot and of a heavily wooded hillside. Vehicular access is currently from Darragh Street under the proposed conditions. There is an existing loading and service area for the existing Salk Hall that is located south of the existing access point along Darragh Street. This area will be maintained and will provide service for the proposed Salk Hall Addition. The development of the Salk Hall Addition will eliminate an existing parking lot; however the proposed layout provides eleven new parking spaces.

The project area is not within any FEMA 100-year flood zone. There are no wetlands on site. |

|

Mechanical Systems:

All occupied areas are served by a system of three manifolded 100% outdoor air handling units with enthalpy energy recovery, humidifiers, and chilled water and steam preheat coils. A set of roof-mounted high-dilution exhaust fans, with redundancy, will provide the exhaust for this system.

An all air variable volume system will provide heating, ventilation, and air condition throughout the building. Phoenix Venturi type laboratory control valves will be use in laboratory and support spaces. This system will include both constant and variable volume air settings for temperature control, as well as occupied and unoccupied settings to reduce energy consumption. Office, conference room, and lobby areas will use commercial grade VAV boxes with reheat.

The Peterson Event Center (PEC) Chilled Water Plant will provide chilled water, at 42°F supply, to the Salk Hall Addition. A new 1200 ton chiller, primary chilled water pump, and 1100 ton cooling tower will be added to the PEC chilled water plant. A decoupling bridge and tertiary pumping system will distribute chilled water to the AHUs and fan coil units. A process cooling water loop, at 85°F supply, connected via plate and frame heat exchangers, will serve laboratory compressors and process loads throughout the building.

Campus steam, at 175 psi, from the Carrillo Steam Plant, is used after pressure reduction to serve AHU humidifiers and steam preheat coils, heat exchangers for HVAC heating hot water, and laboratory and domestic hot water heat exchangers.

|

|

Plumbing Systems:

A new 4-inch potable water supply main will be provided to the new Salk Hall Addition from an existing underground city potable water main. The new main will enter the building on the ground level. A main shut-off valve, water meter, and reduced pressure back-flow prevention assembly will be provided at the entrance location.

The domestic water supply system will be sized to include the building’s plumbing fixtures’ water loads, mechanical systems’ make-up water loads, emergency safety shower & eye wash water loads, laboratory water loads, and exterior wall hydrant loads. Domestic hot water and lab hot water will be generated at the ground floor level via two low-pressure steam-fired hot water generators for lab hot water system and one for domestic hot water system. Each duplex hot water generator for lab hot water system will be sized to satisfy 67% of the estimated system demand upon failure of any single hot water generator. Hot water will be distributed at 120°F. In-line centrifugal pumps will circulate the hot water system.

Sanitary waste from the basement floor to the penthouse will drain by gravity down to a 10-inch sanitary waste building drainage header located under the ground floor level. This sanitary waste building sewer shall be routed to tie into the existing municipal sanitary waste sewer system.

Laboratory waste drainage piping system will be provided to convey laboratory waste and lab equipment drainage by gravity to the municipal sanitary waste sewer system in the street. Laboratory waste will drain by gravity down to a 6” inch laboratory waste main to the ground floor level. The waste will then connect to the sanitary waste system before exiting the building.

A storm drainage system will be provided to convey storm water by gravity from roof and area drains to the municipal storm sewer system. |

|

Electrical & Lighting Systems:

Power will originate from the University of Pittsburgh Central Utilities Plant at 4,160 volts. The medium-voltage feeders will terminate in two substations in the Salk Hall Addition basement. One substation will serve all 480V loads in the building and the other will serve all 208V loads in the new building.

The building distribution will have one 480/277 volt substation with feeders to serve lighting and mechanical panels throughout the building and the motor control center in the mechanical penthouse. The building distribution will also have one 208/120 volt substation with feeders to serve all receptacle and laboratory loads in the building.

Emergency and standby power will be served from a single 600-kW standby diesel generator with a 24-hour supply of diesel fuel at 100% capacity.

The lighting will be designed to provide task and ambient light to support the visual needs, comfort, and security requirements of staff, students, and visitors. The design will include accent and effect lighting to reinforce the architectural design. Lighting equipment will be selected for energy efficiency and simplified lighting maintenance to minimize operating costs. The source for interior lighting will generally be fluorescent lamps operating on high-frequency solid-state electronic ballasts. Compact fluorescent lamps will be used in downlight and wall wash fixtures. Incandescent halogen lamps will be used for artwork, special accent, or dimming applications. Metal halide lighting will generally be used for exterior and parking lot lighting because of its superior color rendering capabilities compared to other HID sources. |

|

Telecommunications:

A Category-5e telecommunications distribution system shall be designed for the building. The system shall include cable tray, Category-5e outlets, cable, and rack-mounted patch panels. The building telecommunications cabling backbone shall consist of 12-strand multimode fiber, 12-strand single mode fiber, and 300-pair copper cables distributed from the first floor MDF to an IDF on each floor.

The building shall be connected to the campus network with 24-strand multimode and 24-strand single mode fiber optic cables to Scaife Hall. Additional fiber optic connections shall include a replacement connection of 24-strand multimode and 24-strand single mode cable between Salk Hall and Fitzgerald Hall. |

|

Fire Protection:

Salk Hall is to be fully protected with a combination Automatic Class I Standpipe/Automatic wet-pipe fire sprinkler system in a Seismic Category A zone. The building fire protection systems will be monitored by the building fire alarm system at the Command Center. Hazardous material storage and use are limited to the maximum allowable per control area limits in accordance with the Pennsylvania Uniform Construction Code. Portable fire extinguishers shall be provided in occupancies and locations as required by the International Fire Code by others. |

|

While great efforts have been taken to provide accurate and complete information on the pages of CPEP, please be aware that the information contained herewith is considered a work in progress for this thesis project. Modifications and changes related to the original building designs and construction methodologies for this senior thesis project are solely the interpretation of Christopher Kelly. Changes and discrepancies in no way imply that the original design contained errors or was flawed. Differing assumptions, code references, requirements, an methodologies have been incorporated into this thesis project; therefore, investigation results may vary from the original design. |

|

Building Statistics |