NEUTRON IMAGING SYSTEM IMPROVEMENTS

| Participants: | Jack S. Brenizer, Professor of Mechanical and Nuclear Engineering |

| M. Mench, Professor of Mechanical and Nuclear Engineering | |

| Kenan Ünlü, Professor of Mechanical and Nuclear Engineering | |

| P. A. Chuang, Ph.D., Mechanical and Nuclear Engineering | |

| K. Heller, Graduate Student | |

| A. Turhan, Graduate Student | |

| Services Provided: | Neutron Beam Laboratory |

| Sponsors: | U.S. Department of Energy-Innovations in Nuclear Infrastructure and Education (INIE) |

| RSEC and Mechanical and Nuclear Engineering Department |

Introduction

The growing demand for dynamic neutron imaging (radioscopy), especially for fuel cell research, has placed new requirements on our existing neutron imaging capabilities. These included developing a more efficient means of data acquisition and storage, better post processing techniques, and a more accurate quantification of water present in the radioscopic images. To this end, the neutron imaging team at the Radiation Science and Engineering Center (RSEC) has made several fundamental and very advantageous changes to its equipment and software resources. The following sections describe the recent upgrades to our imaging and post-collection image processing systems.

Equipment Upgrades

For many years our dynamic imaging system consisted of an analog camera connected to a computer through an analog-to-digital interface card that allowed the capture of 30 fps images at 640x480 and 8-bit grayscale depth. This system provided a stable foundation to support the development of data capturing and post processing procedures. To meet the requirements for our recent fuel cell research, a “turn-key,” completely digital, image acquisition system was added.

Purchased through the company “I-Cubed,” the complete system is comprised of a Pentium IV computer system with camera interface card, a Cohu CCD Camera and image capture software. The computer system is exceptional for both storage of the large volumes of digital image data being captured during radioscopy experiments and the running of the in-house developed, post processing and water quantification software. The digital CCD Cohu camera supplied with the system has a 1004x1004 pixel resolution and a 10-bit deep grayscale range. When connected to the computer’s interface card, frame rates as high as 30 fps are possible. The unique driver set and onboard buffers of the Epix interface card make this possible.

Norpix’s Streampix image acquisition software was included with the computer. Image capturing and storage is done in the form of proprietary image stacks called “sequence files,” which can then be exported to a variety of formats, most notably TIFF and AVI. All post processing is done in the TIFF format since it a lossless image format and can be read on PC, Macintosh or Unix computers. AVI files are convenient when a qualitative, “real-time” inspection of an object is desired. The saved image sequence file can be converted to the AVI movie format and played back on Quicktime or Windows media player without the need for secondary movie conversion software.

The Streampix software also includes the ability to run user-written plug-ins. This feature allows the synchronization of image capture with external devices through the serial port or external data acquisition cards. Capturing an image along with a pressure or temperature reading is now possible, as well as capturing an image at the request of an external device, such as a rotation table signaling proper test subject alignment.

The decision to use a “turn-key” system was based on the desire to avoid incompatibilities between the various hardware components. An added advantage of the “turn-key” system is the accompanying tech-support, which can troubleshoot problems and provide quick solutions.

Post Processing Software Updates

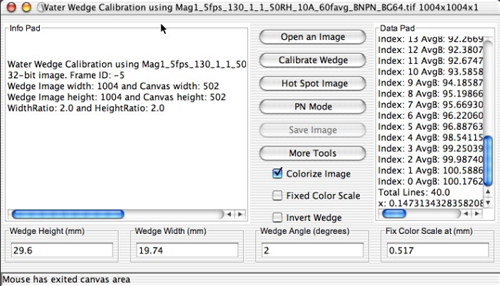

The Penn State neutron imaging team has focused on developing in-house software for data analysis. PSUMagic is the latest incarnation of the PSU Frame Grabber software originally designed for use with the older analog imaging system. With high-speed digital image capture now accomplished through Norpix’s Streampix, an earlier version of PSUMagic was modified to enhance its post-processing and water quantification algorithms.

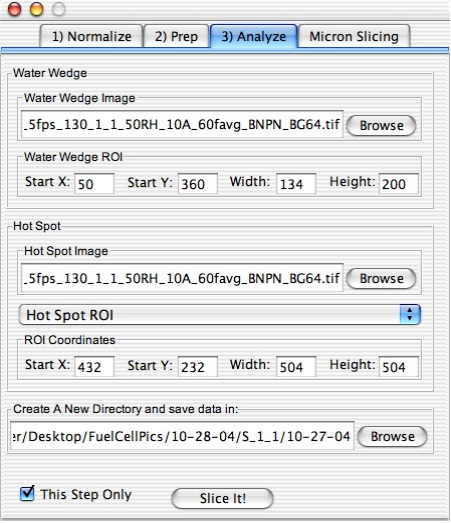

PSU Magic Main Window

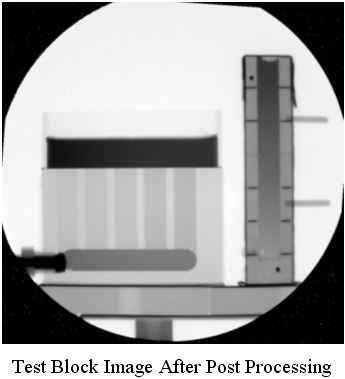

Several post-process image enhancement techniques were incorporated to increase the overall image quality and accuracy of the water quantification process. To account for the random noise in sequential images, the luminance value of corresponding pixels within sequential images can be averaged. To correct for minor fluctuations (typically <<1%) in the reactor power level, which result in changes in the neutron beam flux and consequently the pixel luminance values in a captured image, the beam intensity between each frame is determined and the entire image is normalized accordingly. The PSU Magic software can correct for variations in the intensity of the neutron beam across the image plane using a beam normalization technique (sometimes called “flat-fielding”). Image enhancement techniques to improve qualitative analysis include highlighting water levels in presentations of single images or video clips such as false colorization of liquid water in the fuel cell and a technique that produces an image of only liquid water in the cell.

Many of the aforementioned post processing procedures are used when isolating and quantifying the water present in neutron images. In addition to calculating a water mass, the latest version of PSUMagic can, at the user’s discretion, track the statistical fluctuation in grayscale of the pixels in the recorded images throughout post processing. This is used to provide a measure of the error involved in the calculation of a water mass. By using this latest feature while analyzing a water-filled test block of known dimensions, an average error of approximately 6.5% was found to be associated with a quantified water mass value.

To reduce the users effort when analyzing large numbers of images, a user friendly GUI was included to automate Power Normalization, Flat-Fielding, Water Attenuation Map Isolation and Water Analysis and Colorization.

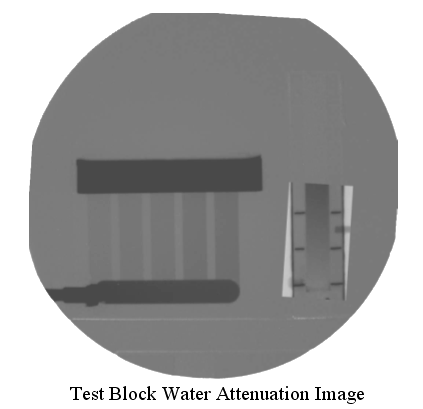

The ability to store individual images digitally allows for easy post-process analysis including ascertaining pixel luminance values of features in the image, such as water within a fuel cell. Consequently, the determination of water content within a cell as a function of time is attainable by referencing a pre-generated calibration look-up table that correlates water thickness to pixel luminance. This table is generated using a water-filled calibration wedge that duplicates the neutron attenuation and scattering effect of the fuel cell. The wedge is the exact distance from the beam port aperture as the fuel cell to ensure the equal beam intensity and hence measured attenuation as the fuel cell.

The wedge contains a water-filled channel of continuously varying thickness. The steady and gradual

decrease in pixel luminance from the bottom to top of the wedge is representative of the increasing water thickness level within the wedge. This luminance data can then be referenced to assign water thickness values to individual areas within the cell or the entire cell as a whole. The mass and volume of water in the cell can then be computed for finite instances or as a varying function of time. This method works well in this application because the water thickness are at most 1 mm, and typically less than 250 mm. Thus, there are essentially no multiple neutron scatters.

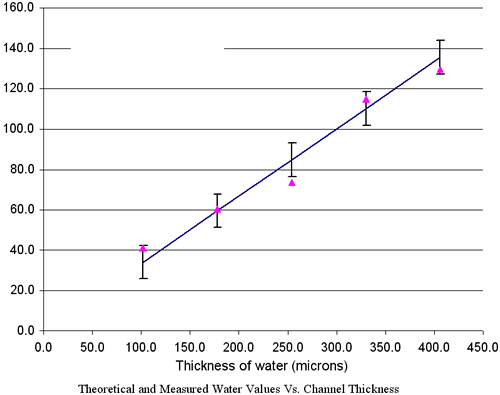

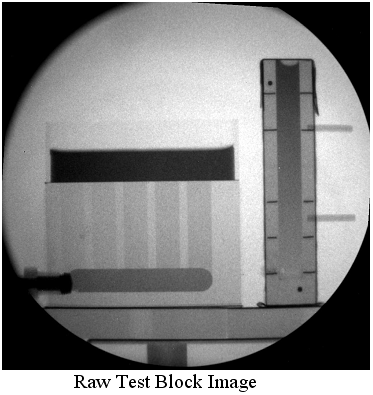

The water quantification procedure was confirmed using an aluminum block milled with channels of known width, height and thickness, filled with water and exposed to the neutron beam where radioscopic images were captured. The post processing and water quantification procedures were applied and the measured values showed good agreement with the theoretical values. The error due to fluctuation of pixel grayscale values was also calculated and plotted.

Future Innovations

Refinement of water quantification in neutron imaging is ongoing. The look-up table method of analysis will be replaced with a fitted equation providing more accuracy.

A Neutron Computed Tomography (CT) system is being developed to compliment our neutron imaging capabilities. The CT system will make use of recent software developments such as the cross sectional reconstruction software, Octopus, and the volume 3-D image generation software, VGStudio Max. A software plugin for Streampix to synchronize turntable movement and image capture has been implemented and is now undergoing rigorous testing. This plugin is undergoing final testing

Further enhancements and upgrades to the imaging system equipment are being explored, including the use of a fiber optic image pipe. This image pipe will provide quick and easy swapping of one camera for another, thus allowing the use of a high temporal resolution camera in a fuel cell experiment and the use of a camera resistant to long periods of radiation exposure in a tomography experiment.