Stronger than One Hundred Men: the Vertical Waterwheel

Historians of technology have distinguished five eras in the history of technology: an era dominated by human muscle power, an era when human power was supplemented by animal power, an era of water power, an era of steam power, and an era of nuclear power. In each of these eras the major source of power, or energy, determined the types of products that emerged and the size of the machinery and tools developed to make these products.

The vertical waterwheel was one of the most important sources of energy to be developed. Invented a century or two before the time of Christ, it was a major turning point in the history of technology. For centuries, man had relied on human and animal muscle power for all kinds of work. The waterwheel enabled man for the first time to use an inanimate power source for industrial production and it had this major impact on technological and industrial development:

Because of its ability to reduce dependence on human labor, to increase productivity, and to carry out tasks nearly impossible with other power sources, the vertical waterwheel became the power source of first choice in European heavy industry by the end of the medieval period. Biringuccio, a mining and metallurgical engineer, wrote in 1654, for example, that "of all the inconveniences, shortage of water is the most to be avoided... because the lifting power of a [water] wheel is much stronger and more certain than that of a hundred men." If there was a single key element distinguishing western European technology from the technologies of Islam India, or China after 1200 it was the West's extensive commitment to and use of waterpower.

For centuries the vertical waterwheel was of critical importance not only to Western technology and to the level of Western industrial output but also to the way Western society evolved. Because water power was not uniformly distributed, it had a major influence on the location of industrial and population centers in Europe. The amount of water power available at any particular site was limited; industrial expansion dependent on it could proceed only so far. There were other ways in which the vertical waterwheel influenced Western social and economic development. Because the vertical wheel was relatively expensive, especially if extensive auxiliary works such as dams, canals, and raceways, were required, its use was restricted primarily to industries that had become dependent on water power. And because the vertical waterwheel was a concentrated power source, it contributed to the concentration of workers at specific sites and to the development of the factory system of production.

Waterpower grew to be a central element in Western technology, industry, and society during the medieval and early modern periods of history primarily because it was a more intensive or concentrated form of power than man or animal power. For most of the era of waterpower, the typical horizontal watermill was capable of generating little more power than a donkey or horse and often not that much. It could be used only for a single task like milling grain and it was wasteful of water. The horizontal wheel did not make possible the performance of large-scale industrial work, work that would have been either impossible or marginal with the animate power sources that were its alternatives. It remained largely an item of peasant culture. The vertical waterwheel, on the other hand, was usually the best means of economically and reliably securing a relatively large amount of mechanical power from a shaft. It was more easily adapted to tasks other than grain milling. And it was capable of delivering more power from a given volume and fall of water than the horizontal wheel. Thus the vertical wheel became the mainstay of European power technology in the medieval period and remained the mainstay well into the 19th century.

It must be remembered also that the vertical wheel does not operate in isolation. It is part of a power system. Dams and reservoirs are required to build up a workable head of water and to help insure regularity of flow. Canals or mill races are needed to lead water from reservoirs or streams to the waterwheel. Sluice gates, flumes, and chutes are often used to control and direct the flow of water onto the wheel. Tail races are needed to carry water away from the wheel once it has been used. Gearing, cams, cranks, and shafts transmit the motion of the waterwheel to the machinery it activates.

Taking this information and applying it to the development of Bethlehem is an interesting exercise. The Moravians were apparently aware of the best technology, including water technology, of their time. They included among their community members men who could apply this technology to their settlement. Hans Christensen, the Danish millwright, for example, transferred a great deal of this knowledge when he designed the waterworks and oil mill buildings and machinery. In the early years of Bethlehem, the flow of the Monocacy Creek was fast enough and the drop deep enough to provide the head of water needed to operate waterwheels in various industries. Undershot wheels were employed in the saw mill, waterworks, and oil mill with one breast wheel (or perhaps two breast wheels) used in the grist mill-fulling mill complex.

The waterpower system employed by the Moravians (see map) encompassed an area of the Monocacy Creek just north of the grist mill-fulling mill complex and extended to the saw mill on Sand Island where the Monocacy emptied into the Lehigh River. It included a dam constructed around the location of the current Broad Street Bridge and a raceway leading to the grist mill-fulling mill complex that provided the water for the grist mill-fulling mill waterwheels then exited the building, passed in front of the butchery, tannery, and tawery, and emptied back into the Monocacy just north of the oil mill where a small island (no longer extant) was located in the creek. A second dam and raceways system was then constructed to service the waterworks and the oil mill complex. The tail race of the waterworks emptied back into the Monocacy in the area of the current Hill-to-Hill Bridge. It is interesting to note that by the time the waterworks and oil mill were running at peak capacity in the 1770s and 1780s, the regulation of the water supply had become a community problem. There were many discussions and disagreements among the master millers about whose industry should take priority in using the water. It was finally decided that tile waterworks needed to take precedence for most of the day and that the other mills would have to work around that schedule.

The Vertical Waterwheel - Three Basic Types

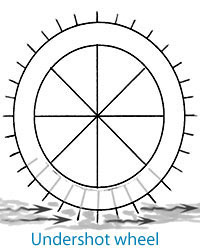

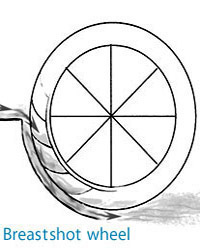

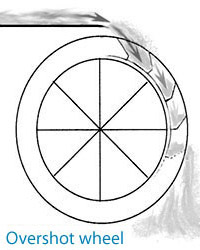

The drawings above show the three basic types of vertical waterwheels: undershot, breast, and overshot. The undershot wheel was used in most of early Bethlehem's industrial buildings because of the low head of water available from the Monocacy Creek. One or possibly two breast wheels were used in the grist mill-fulling complex, however.

A British engineer named John Smeaton analyzed the relative efficiency of two forms of waterwheels, the undershot and the overshot. The average overshot wheel was far more efficient than the undershot, about 65% as opposed to 25%. The undershot wheel is an impulse wheel, since the water imparts its energy by pushing. If the hillside is steep, the water moves fast at the bottom and can push impressively against the paddles of an undershot wheel. The overshot wheel is a gravity wheel. It is a series of buckets attached to the outside of a big circle. The water goes into a container at the top and drops all the way down.

The growth of mills was accompanied by the growth in the power of waterwheels. From the first half of the 18th century to the first half of the 19th century, the average horsepower increased 300% to 12-18 horsepower. the largest wheels were 60 and 70 feet in diameter and capable of producing upwards of 250 horsepower. Taking advantage of America's abundance of wood, most waterwheels were constructed of wood. Usually, only the bearings and teeth were made of metal. However, wooden wheels needed replacement roughly every 10 years.

From the

Collections at Historic Bethlehem [PA]

Return to:

In-Depth Articles

|

||||

|