Building Statistics

General Building Data

Building Name

| George Mason University Student Union Building I (SUB I)

|

Location |

4400 University Drive

Fairfax, Virginia 22030 |

Building Occupant Name |

George Mason University (Owner) |

Occupancy Type |

Group B (Offices, Classrooms), A-3 (Meeting Rooms larger than 750ft2), A-2 (Restaurant, Dining) |

Construction Type |

IA, IB, or IIA, (waiting on response) |

Size |

65,382 GSF |

Number of Stories |

Four Stories |

Dates of Construction |

Start: June 2009

Finish: July 2010 (Estimated) |

Actual Cost Information |

$17.5 million |

Project Delivery Method |

Design Build |

Project Team

Owner

|

|

Architects |

|

Design Builder |

|

Civil Engineer |

|

Structural Engineer |

|

Electrical Engineer |

|

Mechanical Engineer |

|

Fire Protection and

Security Consultant |

|

Architecture

Architecture

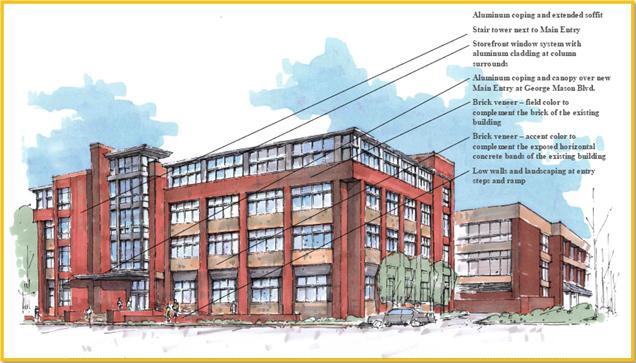

The George Mason University Fairfax Campus has experienced a vast expansion over the last decade. To go along with this development the demand for on-campus student union support and office space has also grown. To satisfy this order GMU has facilitated a 65,382 GSF four story addition to the existing Student Union Building. The project will address offices, student service/activity spaces, and conference rooms. The project will also include site-related improvements like ADA accessible parking, a new food services loading dock, and low walls with addition to landscaping at the entry steps and ramp.

The exterior features will consist of Aluminum coping and extended soffit crowning the top of the building. The brick veneer will consist of a color to balance the brick of the existing Student Union Building and will also have an accent color to complement the exposed horizontal concrete bands of the existing building. Floors one through three will have a storefront window system with brick veneer where the columns are located, while the fourth floor will have a storefront window system with aluminum cladding where columns will be located. A stair tower will be located next to the Main Entry which will be protected by aluminum coping and canopy at George Mason Blvd.

Major National Codes

-

Virginia Uniform Statewide Building Code (VUSBC)(2006 Edition)

-

International Mechanical Code (IMC)(2006 Edition)

-

International Plumbing Code (IPC)(2006 Edition)

-

The National Electric Code Edition (NEC)(2002 Edition)

-

International Energy Conservation Code (IECC)(2006 Edition)

-

Americans with Disabilities Act Accessibility Guidelines for Buildings and Facilities (ADAAG)(2004 Edition)

-

Public Building Safety Regulation

-

Bureau of Capital Outlay Management (BCOM), Construction and Professional Services Manual (2004 Edition)

-

Virginia Statewide Fire Prevention Code

-

Department of Conservation and Recreation – Virginia Erosion and Sediment Control Handbook (Third Edition, 2002)

-

Department of Conservation and Recreation – Virginia Storm Water Management Handbook (Vol. 1 & 2, First Edition, 1999)

Zoning

Waiting on a response.

Historical Requirement

There are no historical requirements for this project. Although the SUB I project must comply with the George Mason University Master Plan.

Building Enclosure

Building Façade

Floors one through four have similar wall enclosures. The wall system consists of 1/2” gypsum wall board with a 7/8” resilient hat channel. This is followed by 6” CMU and 2” R18 Spray applied insulation. Hot dipped galvanized steel masonry ties secure the brick veneer to the CMU. Continuous membrane base flashing and weep holes will allow for proper drainage. All four floors will have aluminum storefront adding ample daylighting to the building.

Roofing

The Student Union Building I has a flat roofing system. The system is comprised of a fully adhered fiberglass-reinforced PVC Energy Star sheet roofing system with a minimum of 3” insulation on metal decking. This roofing makeup is then supported on top of K-Series steel joists. SUB I also has a parapet wall that runs along the outer edge of the roof. The parapet wall has a pre-formed aluminum roof edge with aluminum fascia and trim.

Sustainability

To meet the requirements of DEB Notice 120108- Virginia Energy Conservation & Environmental Standards, Section 709.1, SUB I project will follow the LEED Certification process. But due to the GMU central plant utilizing CFC-based refrigerants and no phase out plan, the project will not meet the prerequisite requirements (EApr3) of the LEED Rating System so the building is not eligible for certification through the USGBC. Hess Construction + Engineering Services will be providing the Bureau of Capital Outlay Management (BCOM) with the LEED documentation. This is a new process for BCOM with no established procedure, Hess Construction + Engineering Services will be providing a “self certification program” which will be a comprehensive, multi-layered review and approval process throughout design and construction that will demonstrate LEED compliance to BCOM. This process will be following the LEED program’s established processes as a basis for compliance, but the building will not be certified.

Primary Engineering Systems Summary

Construction

The George Mason University Student Union Building I project is a four story addition located on the Fairfax, Virginia Campus off Aquia Creek Lane. The project started in June 2009 and is estimated to finish in July 2010. This project is very distinctive in the sense that the construction site is very small. The project has selective demolition on the site to prepare for the incoming addition. The project will also include a 30,000 square foot renovation to the existing Student Union Building, which will mainly include mechanical renovations.

Structural

The structural system used in the George Mason University Student Union Building I is structural steel.

The design loads for the Student Union Building I are as followed:

- Live Loads

- Assembly Areas – 100 psf

- Administrative Offices – 80 psf + 20 psf (Partitions)

- Stairs and Corridors – 100 psf

- Storage (Light) – 125 psf

- Mechanical Rooms – 150 psf (or Heavier per Equipment Weight)

- Roof – 30 psf

- Snow Loads

- Ground Snow Load (Pg) – 25 psf

- Snow Exposure Factor (Ce) – 1.0

- Snow Importance Factor (I) - 1.2

- Flat Roof Snow Load (Pf) – 26 psf + Snow Drift

(All Roof Areas are Designed for Minimum 30 psf Live/Snow Load)

The Student Union Building will use wide flange beams and columns that conform to ASTM A992/A992M–06a. The typical beam is a W21x44 into a W21x44 girder. The wide flange beams range from W12x14 to W21x68. The wide flange columns range from W10x33 to W12x87.The Headed Stud–Type Shear Connectors conform to ASTM A108–07. These are Cold-Finished, Grade 1015 or 1020 shear connectors. Anchor Bolts conform to ASTM A307–07a, the anchor bolts are rated at 60,000 PSI Tensile Strength and are of the non-headed type. High–Strength Threaded Fasteners are specified to conform to either ASTM A325–07, Standard Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength, or ASTM A490–06, Standard Specification for Structural Bolts, Alloy Steel, Heat Treated, 150 ksi Minimum Tensile Strength.

The total floor thickness is 5.5”. The structural slab is comprised of 3.5” 4,000 psi lightweight concrete over a 2” 18 gauge composite steel deck supported on steel beams. The slab is reinforced with 6” x 6” – W4.0 x W4.0 W.W.F.

The roof deck shall be 1.5” 20 gauge Type B steel deck. The roof system consists of a fully adhered fiberglass-reinforced PVC Energy Star sheet roofing system with a minimum of 3” insulation. This roofing makeup is then supported on top of K-Series steel joists.

The structural phasing for the Student Union Building is as followed:

- Phase One – 2nd and 3rd Floors, Northeast portion of SUB I

- Phase Two - 2nd and 3rd Floors, Northwest portion of SUB I

- Phase Three – 4th and Roof, Northeast portion of SUB I

- Phase Four - 4th and Roof, Northwest portion of SUB I

- Phase Five - 2nd and 3rd Floors, Southeast portion of SUB I

- Phase Six - 4th and Roof, Southeast portion of SUB I

- Phase Seven - 2nd and 3rd Floors, Southwest portion of SUB I

- Phase Eight - 4th and Roof, Southwest portion of SUB I

The steel will be erected strictly from the North side of each phase to the South side. The reason the steel is sequenced in this manner is due to the fact that the George Mason site is so tight. The erection of a new Data Center to the North of the project adds further compaction to an already tight site and restricted the steel from being erected from South to North.

Electrical

The Student Union Building I will be a 480/277 Volt 3 phase sytem. The project

has a Total Load for Existing and New Student Union Buildings of 1384.5 KVA, which includes:

- Existing Building Highest Demand Load – 528 KVA

- New Motor Load – 421.8 KVA

- New Receptacle Load – 235.5 KVA

Lighting

The Student Union Building I will have a New Lighting Load of 89.8 KVA. The majority of the lightning will be two types of recessed mounted 2' x 4' flourescents. The fixtures will use 2 T5's for 28 watts per bulb and 2 T8's for 32 watts per bulb. Recessed ceiling mounted compact fluorescent downlights will be used in areas where more light is needed. These fixtures will use two 26 watt tri-tube fluorescent bulbs

Mechanical

The Student Union Building I will have an extensive mechanical system. Mechanical Rooms are located on the 1st and 4th Floors of the Student Union Building Project. These rooms will house two Air Handling Units (AHU). These AHU's will be 30,000 CFM, 460 Volts, 3 Phase units. SUB I will have six types of VAV Boxes with the max CFM ranging from 400 to 1200 CFM, two 700 Nominal CFM Fan Coil Units of 120 Volt, Single Phase, and two Base Mounted 300 GPM Hot Water Pumps of 480 Volts, 3 Phase. Rectangular metal ducts and plenums for HVAC, will be the main distribution system in the building. The pressure classes are from minus 2 inches to plus 10 inches of water gage. These ducts will be Galvanized Sheet Steel of lock forming quality which conforms to ASTM Standard A653/A653M-07.

Fire Suppression

The fire protection in the George Mason University Student Union Building I will follow the 2006 Virginia Construction Code (VUSBC 2006). All Occupancy Areas are Light Hazard (0.10 GPM/SQ. FT.) except Electrical, Mechanical, and Copy Rooms which are Ordinary Hazard Group I (0.15 GPM /SQ. FT.) The type of sprinkler system that will be utilized in the SUB I addition will be a wet automatic sprinkler system. All automatic sprinklers are provided throughout the building with a Group 2A fire area (VUSBC 903.2)