| |

|

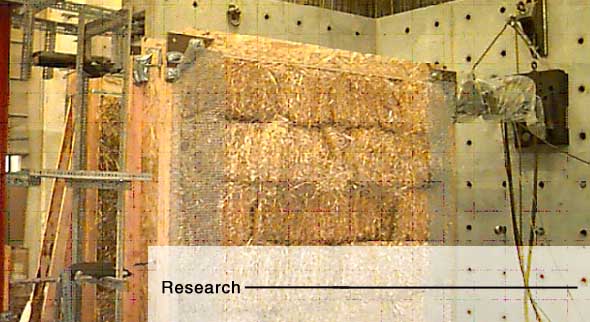

Research in sustainable building technology is currently in progress at Penn State and the University of Washington and is focused on strawbale construction technology and applications. This research program is largely accomplished through the course activities.

Overview of strawbale technology Straw is an agricultural waste product that is typically left to rot or is burned with harmful environmental effects. The slow rate at which straw deteriorates creates disposal problems because, unlike nitrogen-rich hay, straw cannot be used for animal fodder, and stems are often too long to be tilled (King 1996). According to the Department of Agriculture enough straw is produced annually to build over 4 million homes (DOE 1995). Existing State-of-the Art Technology on Strawbale Wall Performance Bearing Capacity –Early test results on the compressive strength of unplastered straw walls found failure at a loading of 333psf [15.9kN/m2] (Lynne and Adams 2000). Platts (1996) tested a plastered wall and found 1/8in” [3mm] of settlement at a loading of 4500 lbs/ft [65.7 kN/m2] which was the limit of their testing apparatus. In recent tests at the University of Colorado, Boulder, three plastered specimens were built, each 8ft [244cm] high, and 12ft [366 cm] long, and subjected to eccentric axial loads simulating a roof truss bearing. Each specimen deflected less than 0.75 inches [2cm] before failing, which failure occurred at 3239 plf [47 kN/m] for a three-string bale wall with polypropylene fiber mesh stucco reinforcing, 3590 plf [52 kN/m] for a three-string bale wall with 20 gauge hex mesh reinforcing, and 6156 plf [90 kN/m] for a two-string (Ruppert and Grandsaert 1999). Typical single story compressive loads range in regions with snow loads range from 845 plf [12 kN/m ] for a 24ft roof span, to 1236 plf [18 kN/m] for a 36ft roof span. Measured elastic moduli range between 50 and 500 psi [345-3450 kPa] largely dependent on density of the bale (Canadian 1995). Bou-Ali (1993) found that bales experienced a 100% recovery after being crushed to half their original height. Recently published reference books on strawbale construction provide limited criteria for loadbearing capacity of straw walls based on empirical test results and high factors of safety (Lynne and Adams 2000). The Pima County, CA building code does set height/width guidelines of 5.6:1, length/width limits of 13:1, and permits 400 plf [5.82 kN/m] in bearing, but leaves seismic engineering up to the professional (Eisenberg 1996). Lateral Strength – Monolithic and cyclic racking tests of plastered walls have yielded results ranging from 1538 plf [22.4 kN.M] (White and Iwanicha 1997, Carrick 1998, and Ramirez and Riley 1998) for walls reinforced with typical 17 gauge stucco wire, to 4500 plf [66 kN/m] for walls reinforced with 16 gauge wire (Nichols 2000). Typical residential shear wall are placed under load ranging from 200-400 plf [3-6 kN/m]. All tests of veneered walls have failed when stucco mesh has pulled away from wood frame. While these tests show the potential of straw walls as shear walls, few engineers are willing to rely on the role of cement stucco in the wall system until more tests have been conducted. Insulating value – Early laboratory tests have found straw walls to have a range of insulating values from between R-26 [RSI-4.6] to R-33 [RSI-5.8](Commins and Stone 1998). The most definitive test were performed at Oak Ridge National Laboratories. Measurements there showed the wall to insulate to R-27.5 [RSI-4.8]. On a per-thickness basis, this is R-1.45 per inch [0.099 W/m°C] (Christian 1998). The insulating value can also be expected to differ depending on bale density due to air content, construction methods that lead to gaps in walls, and straw fiber length, (King 2001) however no tests have accounted for these variables. Rigorous tests of how the density of bales affects insulating value have not been performed, although it could be expected that the lower the density, the more air, and the greater the insulating value of straw walls. Fire Rating – In tests performed by SHB Agra Labs to ASTM E-119 specifications, a plastered straw wall achieved an excess of a two hour fire rating, as temperatures averaging 1942 degrees F resulted in only a 10 degree rise in temperature on the opposite wall face after 120 minutes (Simons 1993). An ASTM E-84 test conducted on an unplastered straw wall showed flame spread index of 10 and smoke development of 350, both less than 2000 International code allowable maximums of 25 and 450, respectively (Fitch 2000). Table 1 summarizes the range of values for strawbale mechanical properties found through testing. These are compared to typical values used in wood frame construction. In each case, strawbale has shown the potential to outperform the wood-framed alternative. Table 1: Summary of Mechanical Properties of Strawbale Construction. Summary: Testing to date has demonstrated wide ranges of performance data, however in each case the results show the potential of bale walls to perform comparably or better than wood framed walls. Recent texts on strawbale construction describe loadbearing methods, but do not provide parameters for loadbearing capacity. (Magwood and Mack 2000, Myhrman and MacDonald 1997). Without predictive design models, designers are forced to work within theoretical boundaries that have been reached by consensus among experienced builders. The use of loadbearing strawbale construction is thus very limited, as code officials and engineers are inclined to rely on post and beam frames to carry gravity and lateral loads, and utilize straw strictly for insulation. This method results in thermal bridging, and degrades the thermal performance of this construction type. |

[ Introduction ] [ Course Info ] [ AE 297H / AE 497H ] [ AE 597 ] [ Research Overview ] [ Current Research ] [ Completed Projects ] [ Partners ] [ Get Involved: Students ] [ Get Involved: Alumni ] Direct questions and comments to the webmaster. Photos: Kate Moxham. |

|