|

|

|

|

|

|

|

|

|

|

|

| |

Note: While great efforts have been taken to provide accurate and complete information on the

pages of CPEP, please be aware that the information contained herewith is considered a work‐inprogress

for this thesis project. Modifications and changes related to the original building designs and

construction methodologies for this senior thesis project are solely the interpretation of Joshua Martz. Changes and discrepancies in no way imply that the original design contained errors or was

flawed. Differing assumptions, code references, requirements, and methodologies have been

incorporated into this thesis project; therefore, investigation results may vary from the original

design. |

| |

| General Building Information: |

| |

|

Building Name: |

|

Appell Life Sciences |

Location and Site: |

|

York College of Pennsylvania, York, PA |

Building Occupant: |

|

York College |

Occupancy or Function Type: |

|

Education |

Size: |

|

102,000 sf |

Number of stories above grade/Total levels: |

|

3/4 |

Primary Project Team: |

|

|

Owner: |

|

York College Of Pennsylvania |

Architect: |

|

Reese, Lower, Patrick, & Scott Architects, Ltd. |

CM: |

|

Kinsley Construction Company |

Civil Engineer: |

|

LSC Design, Inc. |

Structural Engineer: |

|

Macintosh Engineering |

M.E.P. Engineer: |

|

JDB Engineering |

Laboratory Consultant: |

|

United Hospital Supply |

Date of Construction (Start-Finish): |

|

January 2010 to August 2011 |

Actual Cost Information: |

|

Bid Cost ~ $16,000,000 |

Project Delivery Method: |

|

Design-Bid-Build/CM gives college GMP |

|

| |

| Architecture: |

| |

This project is a renovation and addition to the existing Life Sciences Building at York College. The Life Sciences is connected to a main lobby that serves another classroom building and business administration offices. From this main lobby you enter a second lobby just for the Life Sciences. A corridor is connected to this lobby that leads through offices on the first floor and then to two staircases leading upstairs to additional offices, classrooms and laboratories.

The renovation includes a Greenhouse Building located a couple hundred feet to the northwest of the Life Sciences. When walking from Life Sciences to the Greenhouse Building there is an accessible entrance. From the vestibule you can walk through the corridor to laboratories, take stairs at the end up to the greenhouses, or downstairs to more laboratories. |

| |

| Major National Codes/Zoning: |

| |

- 2006 International Building Code (I.B.C.)

- 2006 International Existing Building Code (I.B.C.)

- 2003 ICC/ANSI A117.1-Accessible & Usable Buildings & Facilities

- Spring Garden Township, York County, Pennsylvania

|

| |

| Historical Requirements: |

| Not Applicable |

| |

| Building Facade: |

| |

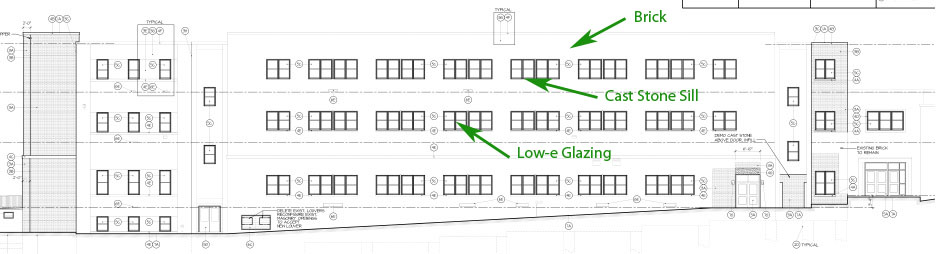

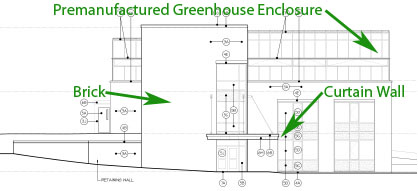

| The majority of the façade for Life Sciences is brick veneer, with cast stone window sills. The glazing is 1” tempered, low e, insulated glass. The façade on the Greenhouse building consists of brick veneer, cast stone sills, aluminum curtain wall systems, and a premanufactured greenhouse enclosure system. The glazing is 1” tempered, low e, insulated glass. |

| |

|

| Life Sciences Elevation |

| |

|

Greenhouse Building Elevation |

| |

| Roofing: |

| |

| Both roofs for the Life Sciences and Greenhouse Building are E.P.D.M systems. This consists of a roof structure, followed by rigid insulation, and then the E.P.D.M roofing membrane. The Life Sciences roof has a cap stone coping going the whole way around the edge. The roofing structure can be found in the structural section of building statistics. |

| |

| Sustainability Features: |

| |

Low-e glazing on the building façade provides for a sustainable feature. Occupancy sensors are used in the Life Sciences and the Greenhouse building. The greenhouses use natural ventilation and evaporative coolers as part of cooling to save energy. There is ans Eergy Recovery Ventilator (ERV) located in the basement Animal Lab to help reduce energy consumption for that space as it is exhausted at high rates. |

| |

| Construction: |

| |

| Construction of Appell Life Sciences at York College of Pennsylvania began in January 2010 and is expected to be completed in August 2011. The construction manager for the project is Kinsley Construction Company. The delivery method for this project was a design-bid-build with the construction manager providing a GMP, guaranteed maximum price. The bid cost for this project was around $16 million. |

| |

| Structural: |

| |

The foundation of the life sciences building is a combination of spread and stepped footing and grade beams. The framing for the building consists of structural steel. Typical beam sizes include W36, W8x15, W14x26 and W24. Typical joist sizes include 14J6, 14J7, 14H3, and 10J14. Roof framing consists of W16x40 and 18LH beams. The dunnage for the two air handlers and two cooling towers on the roof includes W8x18 and W8x24 beams.

The flooring system includes several different slab types including:

Slab 1: 4" Slab On Grade W/ 6x6-W1.4x1.4 WWF Over 6" Crushed Stone

Slab 2: 6" N.W. Concrete Slab On Grade W/ 6x6-W2.9x2.9 WWF Over 6" Crushed Stone

Slab 3: 3" Concrete On 9/16", 28ga Painted UFS Form Deck W/ 6x6-W2.1x2.1 WWF

Slab 4: 4" Slab W/ 6x6-W1.4x1.4 WWF Over Built Up Rigid Insulation W/ Min. 40 Psi Compressive Strength

Slab 5: 4" Concrete On 9/16", 26ga Painted UFS Form Deck W/ 6x6-W2.1x2.1 WWF

Slab 6: 6" Concrete On 9/16", 26ga Painted UFS Form Deck W/ 6x6-W2.9x2.9 WWF

|

| |

| Lighting/Electrical: |

| |

The main supply substation to the building is 15 kV. The main transformer is a 13.2 kV 3 phase, 3 wire, primary, and 480/277 V 3 phase, 4 wire, secondary that services the panelboards. The main switchboard servicing the panelboards is 3000A, 480/277 V, 3 phase, 4 wire. A 300KW/375KVA diesel emergency generator is provided. The main electrical rooms are located in the basement central plant.

The majority of interior lighting is provided by fluorescent and incandescent lamps. Most of the office spaces and laboratories are provided with T8 fluorescent lamp fixtures. General classrooms T5 compact fluorescent lamp fixtures. Computer classrooms are also provided with T8 fluorescent lamp fixtures. The Greenhouse Building interior lighting is provided by T8 fluorescent lamp fixtures. All exterior lighting is provided by clear metal halides. |

| |

| Mechanical: |

| |

The basement of the Life Sciences Building includes a central plant that services chilled and hot water to the systems for the Life Sciences and Greenhouse Buildings. The chilled water system includes 2 cooling towers on the roof to condition the condenser water and an indoor hot and cold water sump tank for freeze protection. There is a 400-ton water-cooled centrifugal chiller that runs on a primary secondary pump system. The primary pumps are located in the central plant of the Life Sciences Building. The secondary pumps for the Life Sciences are also located in the central plant. Secondary pumps are located in the Greenhouse Building mechanical room to service that area.

The hot water system includes 3 2640 MBH gas-fired, vertical finned-tube boilers. Two base mounted hot water pumps, one duty, and one standby will be used to supply hot water to air handling units and any terminal heating units included. There will be secondary pumps provided in the Greenhouse Building mechanical room to supply hot water to fan coil units and any other heating equipment in the Greenhouse Building.

There are 5 air handling units that supply conditioned air to the Life Sciences Building. AHU-1 (4200 cfm), located in the basement, serves the first floor VAV boxes for office spaces. AHU-2 (6900 cfm), located in the second floor mechanical room, serves the first floor primary air fan coil units for classrooms and laboratories. AHU-3 (8000 cfm), located in the third floor mechanical room, serves the second and third floor VAV boxes for office spaces. AHU-4 (8100 cfm), located on the roof serves the second floor primary air fan coil units for classrooms and laboratories. AHU-5 (7550), located on the roof, serves the third floor primary air fan coil units for classrooms and laboratories. AHU’s 2, 4, and 5 are equipped with heat recovery wheels to recover energy from supplying the labs.

The VAV boxes for the exterior office spaces are parallel fan powered and connected to hot water loop to reheat the air before it enters the space. Interior spaces are conditioned using VAV reheat units. The VAV units will be equipped with airside economizers.

The animal lab in the basement will be conditioned with a 1000 cfm outdoor air Energy Recovery Ventilator.

Heating and cooling for the Greenhouse building will be provided by fan coil units using ducted outdoor air direct from outside. The fan coil units will be equipped with water-side economizers. The greenhouses themselves will be cooled with a combination of natural ventilation, exhaust fans, and evaporative coolers. Natural ventilation will be provided by motorized vents. Evaporative coolers include 2000, 2400, and 3200 cfm units for the 5 greenhouses. Heating for the greenhouses will be provided by wall hung hot water radiation recessed in the wall. Horizontal unit heaters will be provided in each of the greenhouses to provide quicker pick up in space heat if it is needed. |

|

|

|