West Village Commons Towson University, Towson, Maryland | |

Patrick M. Morgan | Lighting/ Electrical | MAE/BAE Candidate |

Sponsors

David Mayhew

Towson University

Architecture,

Engineering,

and Construction

Bill Melluish

GWWO Inc. /Architects

Project Architect

Patrick Marquez

James Posey Associates

Electrical Engineer

|

Building Data | Architecture | Building Enclosure | Sustainability Communications | Construction Management | Electrical | Lighting Fire Protection | Mechanical | Structural | Transportation

Project Team

Dates of Construction

Total Cost

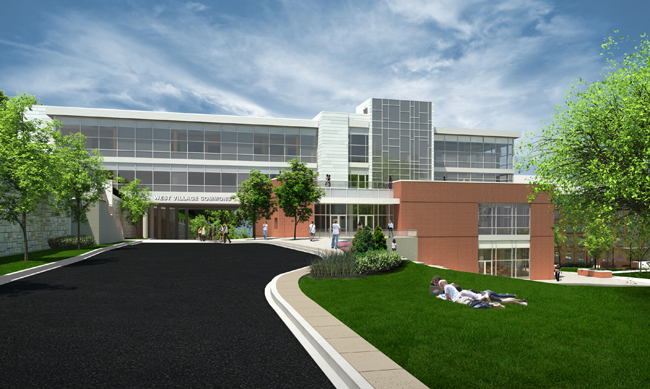

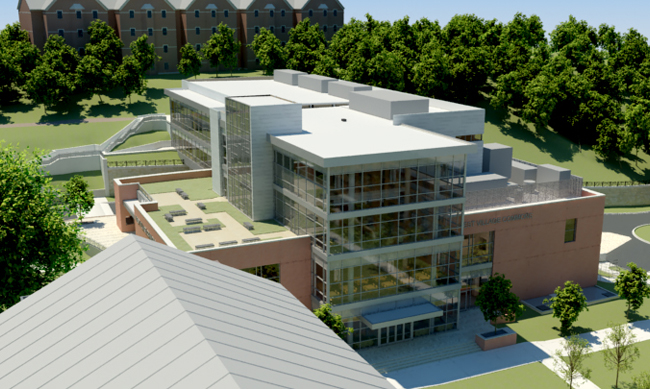

Design and Functional Components Towson West Village Commons is unique in its initial design as it works with the surrounding environment, while providing a unique building for the campus. Considered the west entrance to Towson University, the building incorporates Emerson drive into the building. The basement, first, and second floor are relatively smaller than the third and fourth floor, making room for an underpass for Emerson drive. This incorporates the hillside into the third and fourth floor providing a natural pathway into and out of every floor. Inside of the building, each floor is unique in its intended function. The first floor provides retail food sales along with other building support spaces. The second floor is dedicated to an open style buffet food commons for university students, faculty and staff. The third floor, which spans over Emerson Drive, offers office space, a small fitness facility and open study/lounge space. This floor also offers access out into a garden. This garden acts as a meeting space and the roof for part of the second floor. The fourth floor is predominantly dedicated to a multipurpose room and the second tier of the student study/lounge space.

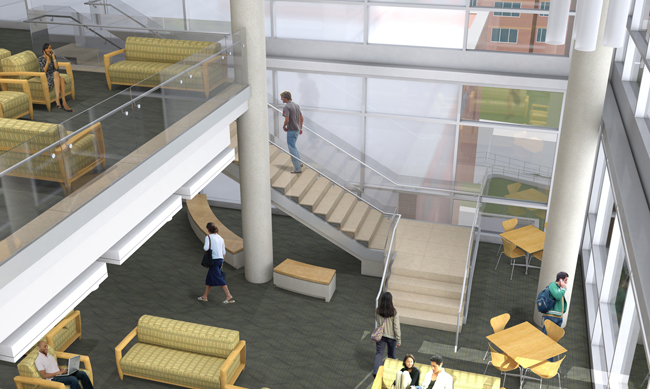

Study Lounge. Courtesy GWWO Inc./Architects Connecting the first and second floors and also the study lounge tiers are grand staircases. Main corridors are kept primarily on the east side of the building. The glass found on the third floor study lounge and along the east hallway face into the center of campus. The views create a place where the vision for Towson can be easily experienced. Whether coming through the underpass, enjoying the roof garden, or enjoying the study lounge, the focus remains on Towson University.

Grand Staircase. Courtesy GWWO Inc./Architects Major Code Requirements

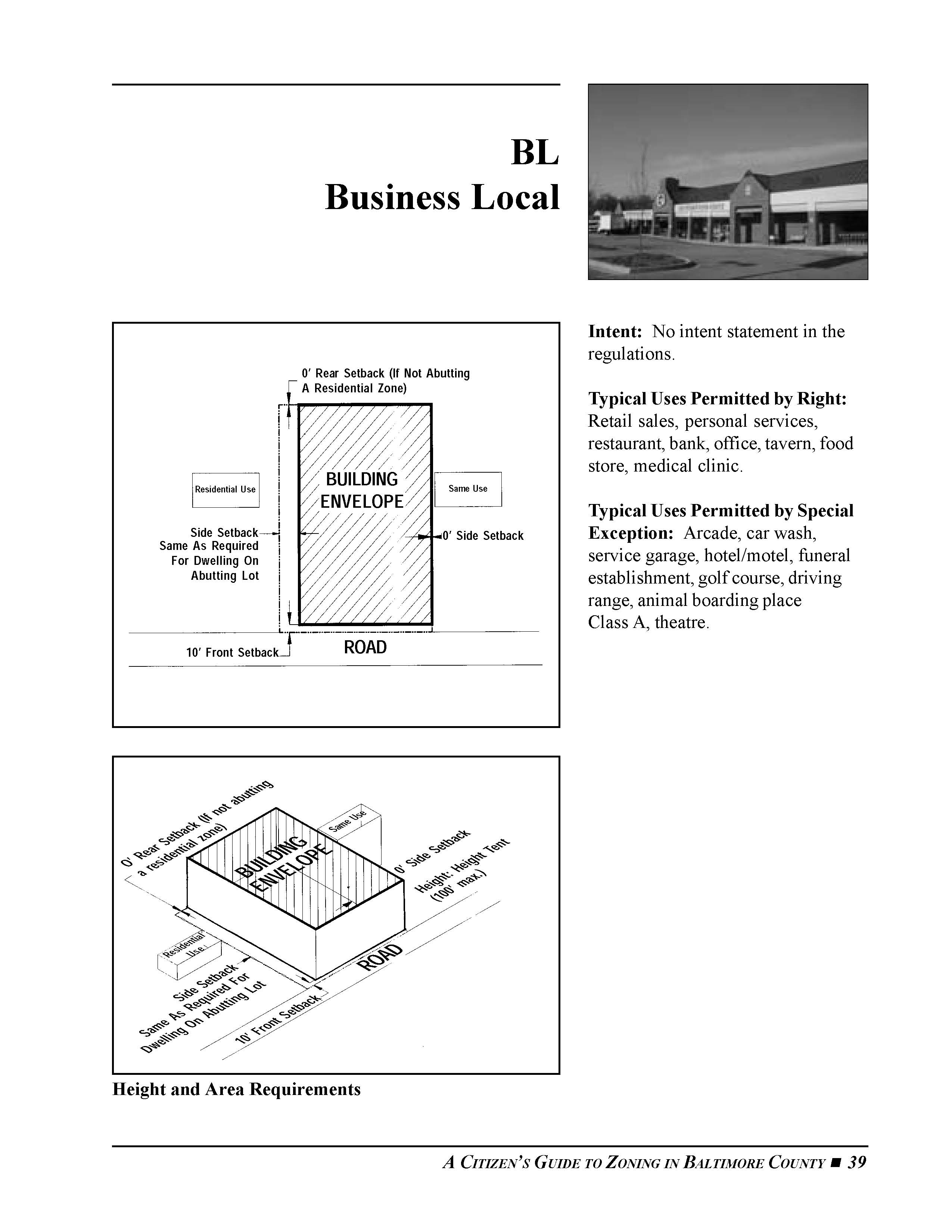

Zoning

Historical Requirements Towson University is working to recreate its image so there is little precedence for the construction of new buildings. Rather, West Village Commons is thought of to be an icon for the new developments being done. Following the new mission statement set forth in 2003, West Village Commons will set the precedent for new construction moving forward.

Building Facades

North Facade Nightitme Rendering. Courtesy GWWO Inc./Architects

East Facade Rendering. Courtesy GWWO Inc./Architects

Roofing

Northeast Corner Rendering. Courtesy GWWO Inc./Architects

According to the University Master Plan, all new construction will strive for LEED certification. Using LEED version 2.2, West Village Commons is estimated to be awarded at least Silver Status. Most credits will be determined by material use and construction methods. Existing trees will be preserved as per detailed plans provided by the landscape architect. An intensive green roof serves as a roof garden on the 3rd floor and helps to manage some water drainage. Water management for the site is a high priority due to the building relationship with an adjoining hill. The 3rd and 4th floor study lounge optimizes the use of fritted, translucent and clear low-E glass to provide daylighting to the space. The overall building is not daylight compliant due to its highly unusual shape and location. The metal panel exterior and high albedo roofing material prevent a heat island effect by the building. Inside of the building, lighting fixtures were chosen based on energy usage and low flow fixtures were used in restrooms and other locations throughout the building. Fluorescent light sources were used as a way to reduce energy consumption in the building. An energy model was developed, and while a large portion of the façade was glazing, the building still reduced its energy consumption by 22% when compared to buildings of a similar nature.

The system branches from the campus feed for Towson Run Apartments. The system enters the building through Boiler Room 001 and is distributed through the building with cable trays until eventually reaching individual telecom closets. Cabling is consistent with the category 6 cable for data outlets. Voice outlets will utilize category 5E cable. Between telecom rooms, the cabling will consist of 12 strand single mode and 12 multimode fiber optic cable for data and 100-pair cable for voice. Racks found in each telecom room will tie into the main telecom room, room 117. This also houses the telephone switch. Almost every room will have a telephone and data connections. A coxial audio/visual system will also be imployed in most rooms.

The CM at Risk management technique was used to help the university guarantee a maximum cost for their project. For Barton Mallow, CM at Risk offered many benefits for both LEED certification and construction scheduling. The primary focuses of the project were time, budget, and LEED accreditation. Since Towson Run Apartments and other residence halls will be in use, it is imperative to minimize the construction impact on student living. Because of these constraints, Barton Mallow chose to schedule using milestones and use two bid packages for subcontracting work. The milestones were effective ways to condense the site area and minimize construction impact. The bid packages allowed for fast startup on the concrete and steel placement along with keeping site workers to a minimum. As with LEED accreditation, building materials and construction management were a big influence. Onsite is a 60” Oak tree that must be maintained throughout the construction process. Close work between the construction manager and the landscape architect was required to avoid damaging the tree. Between site preservation and logistics, an estimated 9 LEED points can be obtained for this project. Towson University has been happy with the less than 2 year construction time and GMP of around $31,000,000 for the efforts to improve the campus while minimally affecting the campus. Current Construction Zone

West Village Commons uses a fairly simple radial distribution system to supply power throughout the building. Only one 2000A main switchboard is required to power the building. Focused around the electrical room found in the basement, 480Y/277V, 3Ph, 4W and 208Y/120V, 3Ph, 4W systems run throughout the building. Transformation between power systems occurs in the basement with either pad mounted or wall mounted dry-type transformers. The 480Y/277V system primarily services the mechanical, lighting and snow melting loads. For the rest of the loads, a 208Y/120V system is in place. 208Y/120V power is also in place for the rented retail food spaces. Many of the panel boards are protected by main circuit breakers along with other systems being protected by enclosed circuit breakers. In case of emergency, an outdoor 150kW natural gas generator can supply power to life safety, standby and elevator loads through automatic transfer switches. In the case of a long term power disruption, a 2000A quick connect switchboard can be used to bring power into the building. This quick connect switchboard is located outside of the building and has the ability to supply both Towson Run Apartments and West Village Commons. The power available to the West Village Commons building form the generator is tied directly into the main 2000A switchboard, so all loads are carried.

The buildings fire protection is branched off of the domestic water connection made in the boiler room in the basement. This services both sprinklers and fire hose cases on each floor. At certain points in the building, including the roof, there is a 2-1/2” fire hose connection to provide quick connection for firefighting services. Based around a control panel found at the second floor vestibule, the fire alarm system has various monitors, pull stations and strobes and speakers located throughout the building. To set off those systems, various smoke and heat detectors are located throughout the building. The fire alarm system ties into the elevator controls and access controls for various door locations.

Towson West Village Commons set out to be a signature building on the west side of campus at Towson University. The building’s LEED accreditation and stunning design is to impress visitors, students and faculty. The use of recessed fixtures proves a dominance of the architecture. Lighting is adequate in most spaces with a few enhanced spaces. The student lounge is a premiere spot and the latest lighting technology is employed to bring color and “pop” to the space. As seen by all students from the quad, the exterior of the building looks in on this spectacle of light. After analyzing the current conditions, the lighting scheme has both high and low points but does achieve one primary goal, energy efficiency. Along with a minimal lighting power density, controls are a stand out feature for most of the spaces. The general spaces are tied together through a building digital control system. This allows for programmed scenes and varying lighting uses depending on the occupant. The multipurpose room on the fourth floor is especially interesting from a control stand point. The space can be controlled through one panel for a single lecture hall or the complete 8,000 sq ft space.

The mechanical system is based around seven variable air volume air handling units. The seven air handling units serve various areas in the building. Certain units handle entire floors, while one dedicated unit handles the office spaces. The seven air handling units, 5 roof mounted and 2 interior, serve over 90 separate supply grilles. Because of the kitchens found on the second floor, 100% outdoor air is required to exhaust certain pieces of equipment. Two make up air units are found on the roof of the second floor on the west side of the building. Each of the make-up air units can exhaust over 4,500 cfm. Spaces such as telecom closets and dry storage are served by an independent ductless split system. Along much of the glass curtain wall system, a perimeter finned heat radiation system provides heat to offset the loads of the air handling units in those spaces. To serve all of these systems, domestic water is supplied to the building. Once reaching the building, a chiller and two gas fired boilers generate either the hot or cold water needed to serve the different systems. To further reduce the energy, a 300 ton induced draft counter flow upblast cooling tower is employed. The chiller is also rated as a variable flow 300 ton chiller system. The two boilers are specified to be gas fired, 3,000 MBH units.

There are two distinct structural systems used to support West Village Commons. The primary super structure for the North end of the building is poured and precast concrete. Most columns throughout the north end are either 24” x 24” or 24” in diameter. These columns are supported by a substructure made of spread footers and grade beams. The grade beams once again conform to the 24” x 24” size. Footers and grade beams use a 4,000 psi concrete mixture while columns and slabs use a 5,000 psi concrete. Typically a 9” floor slab will be seated on a concrete column with the addition of a 7 1/4” thick drop panel. For additional strength and safety concerns, the elevator shafts and stair wells are 12” thick shear walls, using 5,000 psi concrete. All slabs, beams, columns, and walls are reinforced using various rebar sizes and counts. The south end of the building uses a steel moment frame to bridge over Emerson drive. The steel is joined to concrete footers in the hillside at the south end. From these steel columns, steel beams project out towards the north end of the building. Due to the curvature of the underpass, there is no typical steel beam size. W36 and W24 sized steel provides the base level structure above the underpass. A composite slab of 3-1/4” reinforced concrete and 2” 20 gauge composite steel decking sits on top of the composite steel beams. All column and beam connections use a double angle shear connection. To tie the building together, steel beams sit on the outermost reinforced concrete columns and are connected with shear studs.

West Village Commons has a unique experience when traveling through the building. Every level exits out of the building. The third and fourth floors use the newly constructed hillside path as both a means of egress and a landscape element to the building. The second floor exits out onto an existing path along Emerson drive. While traversing through the building, there are many ways to venture from floor to floor. The grand stair is a signature element to building and is primarily used by students entering from the quad. As one reaches the third and fourth floors, the grand stair is no longer available. A replica of the grand stair can be found in the student lounge at the north end of the building. Two stairwells are located in the interior of the building for occupant use to go from the basement to the fourth floor. Elevator A is located within the kitchen space and is sized for delivery usage. Elevators B and C are primarily for occupant use.

|

||||||||||||||||||||||||||||||

Note: While great efforts have been taken to provide accurate and complete information on the pages of CPEP, please be aware that the information contained herewith is considered a work‐in progress for this thesis project. Modifications and changes related to the original building designs and construction methodologies for this senior thesis project are solely the interpretation of Patrick Morgan. Changes and discrepancies in no way imply that the original design contained errors or was flawed. Differing assumptions, code references, requirements, and methodologies have been incorporated into this thesis project; therefore, investigation results may vary from the original design. |