|

Building Name: |

Production Building |

Location: |

Virginia, USA |

Occupant: |

CBD Chemical* Name changed for confidentiality |

Occupancy |

High Hazard, Chemical Manufacturing Plant |

Project Team: |

Withheld at the request of project team |

Size: |

55000 GSF |

Cost: |

$125 Million |

Stories Above Grade: |

5, plus a mezzanine in the first floor and a penthouse roof |

Dates of Construction: |

April 2008 - January 2009 |

Project Delivery Method: |

Design-Bid-Build |

Contract Type: |

Negotiated Guaranteed Max Contract |

Building Occupancy and Use

|

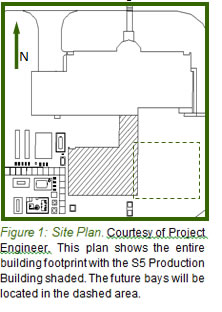

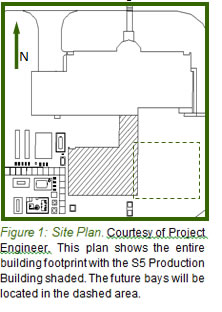

is also connected to the existing two-story building. The two story building houses the majority of office space. Most of the chemical production equipment will be located on the first floor although much of the facility will have production space, laboratory space, and support. The existing two story building houses the majority of office space; however, the second floor of the production building incorporates some as well. The entire addtion was designed to easily expand future bays to the east. Figure 1 shows the entire buidling footprint of the site with the chemical prodcution plant addition shaded in grey. Due to the chemical production at the plant the occupany type is high hazard and the construction type is type 1A, non-combustable.

Building Enclosure

Architecture

The Production Building is an addition to existing site with laboratory and chemical manufacturing space owned by CBD Chemical*. CBD Chemical had occupied the site prior to construction of the S5 Production Building. The company produces drug substances and intermediates for the pharmaceutical industry. Each facility on site is a FDA inspected cGMP facility. This five-story addition includes a penthouse roof as well as a mezzanine level in the first floor a where it

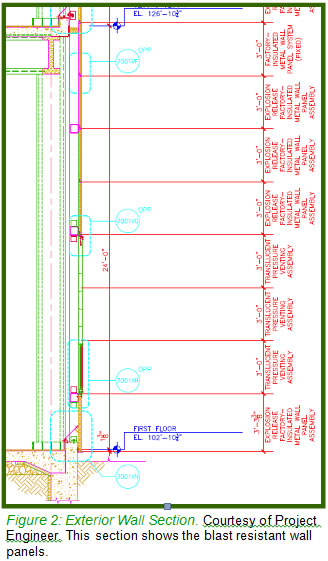

The massing of the Production Building is pretty simple. The exterior skin is a combination of insulated metal panels and translucent wall panels. The north and south facing walls have horizontal strips of windows, while the West end has a vertical strip of windows. Due to the highly explosive nature of the chemical production the skin of the building was designed as explosive release wall assemblies.

Zoning occupancy for the S5 Production Building is M-2 Heavy Industrial in accordance with the Virginia Zoning adopted in 1971 with amendments. There is no minimum to the lot size, lot width at building line, or lot depth as well as no maximum to impervious coverage. The maximum height is 76 feet or 6 stories. The construction type is type 1A, non-combustible.

Historical

Requirements

Governing Codes

and Regulations

Zoning

- Virginia Statewide Fire Prevention Code

- Virginia Uniform Statewide Building Code

- International Building Code 2003

- ICC International Electrical Code 2003

- International Energy Conservation Code 2003

- International Fire Code 2003

- International Fuel Gas Code 2003

- International Mechanical Code 2003

- International Performance Code for Buildings and Facilities 2003

- International Plumbing Code 2003

- International Urban-Wildlife Interface Code 2003

Mechanical System

No historical requirements need to be met.

Facade:

The building is a steel frame structure. The exterior skin is a combination of insulated metal panels and translucent wall panels. Some of the metal wall panel assemblies are fixed while others serve as the explosion release wall assemblies. These wall assemblies are factory-insulated metal wall panel systems.

Roofing:

The roof will be comprised of concrete on metal deck. This system then covered by a EPDM waterproof membrane.

Sustainable Features

No Sustainable Features included in this project.

Sustainable Features

The structural system for the Production Building is moment frame structural steel. The first floor has an 8 inch slab on grade while the other four floors have normal weight concrete on metal deck. Each beam works compositely with the slab above. The foundation system for CBD Chemical's Production Building is precast concrete piles. On top of the concrete piles are spread footings with piers that extend up to the concrete tie beams that span between each column. The lateral system for the Production Building is comprised of steel moment frame connections. Each column has moment connections in both the North-South and East-West directions. The mezzanine does not contribute to the lateral system.

Electrical System

Structural System

The Production Building has two 5600 MBH has-fired boilers, two 507 ton cooled screw chillders, and two AHUs. One small AHU serves the boiler building, while the large AHU serves the Production Building. The system is a constant air volume system with terminal air units which condition the air for each space locally. The large AHU uses an energy reclaim coil using a 30% glycol solution.

Conveyor Systems

The electrical system has three service entrances at 480/277V. One power the motors and control centers, one powers control centers and chillers and the last controls PBP panels which power the heaters. There are small transformers for lighting/receptacle loads. A UPS at 208/120V serves emergency lighting loads.

Construction

Fire Protection

Special Systems

The production Building was a design-bid-build project and construction ran from April 2008 to January 2009. The contract was a negotiated guaranteed max contract. The total project cost was $125 million. The project team and construction managers were withheld at the request of the project team.

The production building was built to a 3 hour fire rating. The steel members were sprayed with cementitious fire proofing. Wet sprinkler systems were used throughout the building. The fire detection and chemical detection systems were combined and use fiberoptic dectection panels. There are 4 airlock systems to seperate the different production areas.

The Production Building has three stairwells as well as an elevator for vertical circulation. The elevator is a freight elevator able to transport large pieces of equipment.

Card access security systems are in place to enter any production areas as well as the robing areas. There are chemical detection systems in place in order to ensure the safety of the production floors. In addition there are multiple process piping systems used in the chemical production process, which are withheld at the request of the owner.

| Note: While great efforts have been taken to provide accurate and complete information on the

pages of CPEP, please be aware that the information contained herewith is considered a work in progress

for this thesis project. Modifications and changes related to the original building designs and

construction methodologies for this senior thesis project are solely the interpretation of Christina DiPaolo. Changes and discrepancies in no way imply that the original design contained errors or was

flawed. Differing assumptions, code references, requirements, and methodologies have been

incorporated into this thesis project; therefore, investigation results may vary from the original design. |