|

|

|

General Building Data |

Building Name |

Reva and David Logan Center for the Arts |

Location and Site |

915 E 60th St, Chicago, IL, 60637 |

Building Occupant Name |

University of Chicago |

Occupancy or function types |

Multidisciplinary arts center |

Size |

184,000 square foot |

Number of stories above grade |

11-story tower with 3-story adjacent building. |

Primary project team |

|

Owner |

University of Chicago |

Project Manager |

Eric Eichler, Senior Project manager at The University of Chicago |

Design Architect |

Tod Williams Billie Tsien Architects LLP www.twbta.com |

Associate Architect |

Holabrid & Root www.holabird.com |

Structural Engineer |

Severud Associates www.severud.com |

MEP Engineer |

Ambrosino Depinto & Schmieder Consulting Engineers www.adsce.com |

Lighting Design |

Renfro Design Group www.renfrodesign.com |

Landscape Architect |

Hargreaves Associates www.hargreaves.com |

Civil Engineer |

David Mason & Associates www.davidmason.com |

LEED Consultant |

Steven Winter Associates, Inc www.swinter.com |

Construction Manager |

Turner Construction, LLC www.turnerconstruction.com |

Dates of construction |

|

Start Date |

June 2010 |

Completion Date |

October 2012 |

Cost |

$114,000,000 (overall cost) |

Project Delivery |

Design-Bid-Build |

Architecture

|

The Reva and David Logan Center for the Arts is inspired by the "flat prairies of the Midwest and the great towers of Chicago", the art center is comprised of a light-filled glass and stone tower and a three-story "Plains" building with saw-tooth roof. "Plains" building is lit by north facing skylights and houses beautifully lit studios, a gallery, music practice rooms, a 450-seat auditorium, a 120-seat Theater and a black box theater as well as a 2,000 square foot exhibition space. The 170-foot tower houses a performance penthouse, screening room, rooftop deck, classrooms, rehearsal rooms, and performance labs on different floors and connected these programs with generous elevators and stairways with offering dramatic distant views of Lake Michigan and downtown Chicago. |

Major national code |

|

- |

Illinois Chicago Building Code |

- |

Illinois Chicago Municipal Code |

- |

Illinois Chicago Mechanical Code |

- |

Illinois Chicago Energy Code |

- |

Illinois Chicago Electrical Code |

- |

International Building Code |

- |

National Electrical Code |

- |

National Fire Alarm Code |

Zoning |

Subarea I - Planned Development #43, Chicago Zoning Ordinance |

- |

Maximum Floor Area Ratio (FAR): 2.20 |

- |

Maximum Percent Site: 46.00% |

- |

Maximum Building Height: 200ft |

Historical requirements |

Not application |

Building Enclosure |

|

Windows |

|

- |

Clear Vision: Low-E insulated glass, Low-IRON outer lite, Neutral High-performance |

- |

Skylight Glazing: Clear outer lite, Neutral High-performance, Low-E on Surface |

- |

Translucent Reflective Spandrel: Low outer lite, Reflective pyrolitic coating |

- |

Laminated Glazing: Laminated Lite, Clear lite |

- |

High Performance Acoustical Glazing: Laminated lite, low-IRON lite, PVB, Low-E coating |

Building facades

|

The Building facade is generally consists of limestone, painted steel sheet and curtain wall systems which is aluminum framing with 4-side structurally glazed insulated glass units. Exterior Insulation and finish system (EIFS) is applied to this building. |

Roofing

|

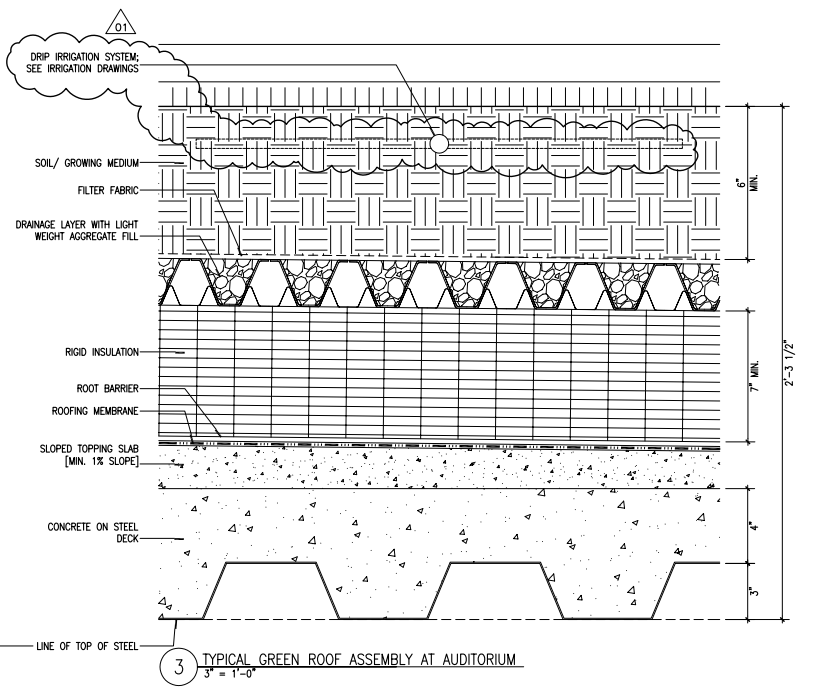

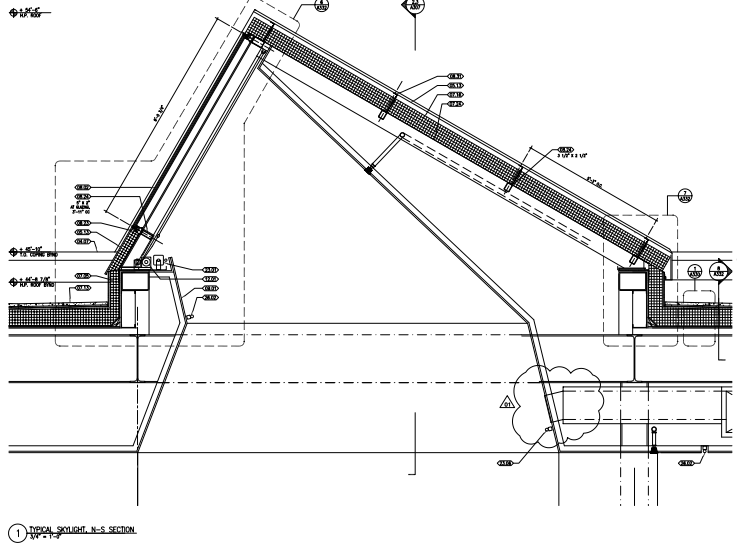

The roofing system is considered as two types which are solar panel with skylight, and green roof. The Skylight roof is shaped as saw-tooth, it is 4-side structurally glazed insulated laminated glazing on aluminum skylight framing, and mounted on HSS framing. On the other side, Solar panels have been installed. For the green roof, there are 7 different botanic, with medium growing soil is covered above the light weight aggregates with filter fabric on the roof of theaters. As supplier's requirement, the gravel zone is installed on the edge of soil. Please refer to the attached drawing below for the specific. |

Figure 1 - Green Roof Assembly at Auditorium |

|

Figure 2 - Skylights Section View |

|

Sustainability Features |

|

This project is submitted for Leadership in Energy and Environmental Design (LEED) certification to the US Green Building Council. |

|

Version: |

LEED 2009 for New Construction |

Rating: |

LEED Gold Certification. |

| - Ground and water source heat pumps | |

- Radiant heating and cooling system |

|

- Saw-tooth skylight |

|

- Three green roofs |

|

- Daylighting |

|

| - Solar panels roof | |

Construction

|

The primary construction management firm for the Logan Center for the Arts is Turner Construction Co. The schedule construction operation in the sequence is used to obtain the best results where installation of one part of the work depends on installation of other components, before or after its own installation. Total size of the Logan Center for the Arts is 184,000 SF, and the building consists of 11-story tower with 3-story adjacent building. Since the project site was adjacent to the existing building which is Midway Studio, the building envelop restoration of adjacent Midway Studios and extension of south campus utility corridor is started first before the foundation excavation. The construction date is from June 2010 to October 2012 with $114,000,000 overall cost. The project delivery method is Design-Bid-Build. |

Electrical

|

(2) 12.47kV primary service from the power company is fed into the Logan Center for the Arts. There is a service transformer to step down into 480/277V on the outside. Two service switchboards (SS-1, and SS-2) serve three main distribution switchboards with 480/277V which are HV-EM-LL, HV-DP-LL-S2, and MDSB. The dry-type transformer is used to step down into 208/120V for the panelboards to serve the lighting loads, receptacles, and other loads. There are two emergency services from the power company to serve the fire pump, and low-voltage switch boards for the emergency lighting loads. In addition to the emergency service systems, there is (1) 600kW diesel-powered engine generator on the lower level. This generator with automatic transfer switch systems serves main mechanical loads, fire pump, and low-voltage switchboard in case of power outage. |

Lighting

|

As the Logan Center for the Arts building is for the multidisciplinary center for the arts, the primary lighting system is divided into the general lighting and theater lighting systems. Fully recessed compact fluorescent 6" aperture downlight is used for the corridor and the lobby. In addition, fully recessed compact fluorescent wallwasher is used for the wall of the lobby for the events such as gallery. Surface side mounted fluorescent linear single lamp T5HO and recessed fluorescent T5HO with frosted acrylic are used for the most of the studio rooms on the first level. For the special rooms including performance studio and rehearsal room, custom light fixtures are used based on the purpose of individual activities. Linear fluorescent T8 fixture with various mounted types is used for most of the classrooms. For the theaters such as auditorium, Studio Theater, and Black Box Theater, the orchestra light fixture and worklight fixture are installed. To control the daylight during the daytime, the motorized shaded is used. |

Mechanical

|

(11) Custom air handling units serve the entire building. Each of three air handlings unit with single zone type serves the Screening room, Black Box Theater, and Studio Theater. (1) Air handlings unit with displacement type serves the auditorium with 13,500 CFM. All AHU's are located at the lower level except the one AHU with 23,500 CFM to serve the tower. (1) Air-cooled chiller is located at the outside of the building to serve the theaters. It is served by one chilled water pump with 125 pressures and 175 GPM. (2) Hot water pumps with end suction type and (2) heat exchangers with U-tube type are located at the steam room on the lower level. They serve the heated water with (2) domestic hot water heaters. Variable frequency drive devices are equipped for most of the HVAC equipment. |

Structural

|

The main structural system of the Logan Center for the Arts consists of steel columns, beams, and diagonal bracing frame. The slab construction is 12 inch thick cast-in-place concrete flat slab reinforced with a continuous #5 @ 8 inch on center bottom grid placed. Typical beams of adjacent building are W14 x 22, W16 x 31 or 36, and W18 x 40, while the typical girders are W21 x 50. Typical beams and columns of tower are reinforcing concrete systems. The roof system of the adjacent building consists of W10 x 15 for beam, while girders are W36 x 150. The lateral bracing frame system is applied to the adjacent building, and it consists of HSS6 x 6 x 1/4, 3/8 and 1/2. |

Fire Protection

|

750 GPM fire pump with (2) 8" incoming and (1) 4" incoming domestic water services serves the fire protection system for the entire building. In addition, the wet sidewall type sprinkler is used for the stair enclosure. The various type sprinklers which are heads, upright, pendent and concealed types are used based on the purpose of the space. |

Transportation

|

The Logan Center for the Arts has vertical transportation system which is elevator. On the north of the building, (2) passenger elevators with ADA auto dialer telephone are located to serve all floors including tower. They are traction system and connected to each motor which are 40HP and 60HP. For emergency case, those motors are fed by emergency switchboard. On the south of the building, (1) passenger elevator and (1) freight elevator are located to serve only floors of the adjacent building. They are hydraulic system and connected to each motor which are 40HP and 75HP. |

Telecommunications

|

(4) Low voltage telecom service entrances with 4" sleeves are located on each north and south of the lower level. Network closet rooms are located on every floor of the tower to serve the data services such as the phone. (5) Outdoor cameras and indoor fixed cameras are installed for security purposes. In addition, the card reader devices are used to access from the outside to inside of the building with local audible alarm devices or into the special rooms such as AV control rooms, network closet, theater backstage, studio, and supply rooms. |