Building Statistics

General Building Data |

|||||||||||||||||||

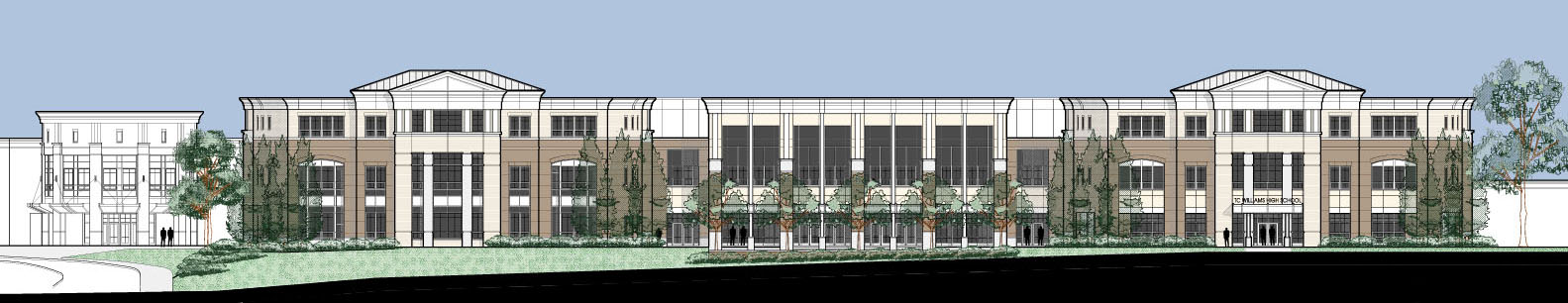

Building: |

T.C. Williams High School | ||||||||||||||||||

| Location and Site: | 3330 King Street |

||||||||||||||||||

| Building Occupant: | Alexandria City Public Schools (Grades 9-12) | ||||||||||||||||||

Occupancy or Function Types: |

Educational Facility - School | ||||||||||||||||||

Size (Total Sq. Ft.): |

469,507 sf (School Structure Only) | ||||||||||||||||||

Number of Stories Above Grade / Total Levels: |

3 Floor Levels |

||||||||||||||||||

Primary Project Team: |

|

||||||||||||||||||

Construction Dates: |

|

||||||||||||||||||

| Actual Cost Information: | $90 Million (Approximate Overall Project Cost) |

||||||||||||||||||

| Project Delivery Method: | Original Delivery: Design-Bid-Build |

||||||||||||||||||

Architecture |

|||||||||||||||||||

Design / Functional Components: |

The structure is designed to provide the school district with all of the amenities required to facilitate the education of its students. T.C. Williams high school contains ample administration and standard classroom spaces as well as specialty classrooms (biology, marketing, chemistry, etc.), a planetarium, computer and science labs. A large commons area provides students with a pleasant dinning experience without having to leave the campus or exposing them to the traditional cafeteria style facility. The large auditorium has operable partitions that can be closed to create multiple lecture halls and for those students who have children of their own, they can now bring their babies to school with them. The “babies with babies” program provides daycare services to toddlers and infants which in turn creates a living lab to teach teenage parents, or expecting parents, appropriate parenting skills. An auxiliary gymnasium was added to provide additional multipurpose space for the main gymnasium. Protruding from the main classroom towers are the music suites and auto service technology shops. |

||||||||||||||||||

| Major National Model Code(s): | 2000 International Building Code |

||||||||||||||||||

| Zoning: | Zoning Ordinance |

||||||||||||||||||

| Building Envelope | |||||||||||||||||||

Exterior Wall Systems: |

The majority of the exterior wall system is face brick with CMU backing and an architectural precast concrete ribbon around the perimeter of the building and below third floor window units. The east and west sides of the facility contain architectural precast concrete coping and the court is enclosed in a pre-finished aluminum curtain wall. Aluminum curtain walls also span from the majority of second floor to first floor window units. The fascia on all elevations of the school is constructed of aluminum composite panels. |

||||||||||||||||||

Roofing Systems: |

T.C. Williams' roof is primarily a Thermoplastic Polyolefin (TPO) Membrane system on a steel roof deck. The clerestories, which were constructed to allow natural light to enter the building through the roof, utilize pre-finished standing seam metal roofing systems except for one clerestory that has an EPDM membrane system. A pre-finished, sloping, standing seam, metal roofing system accents the two main entryways into the school facility while the garden roof assembly obtains additional LEED points. |

||||||||||||||||||

| Building Systems | |||||||||||||||||||

| Demolition: | Phase A-1 was the demolition of the existing one story, career tech wing that was built on to the original school structure in the 1970’s. The 22 ft. high structure required abatement for asbestos. Since the lead paint was contained, no abatement was required to remove the lead. After the new school facility is completed, phase B-1 will commence. In this phase, the existing three story, 45 ft., T.C. Williams High School building will be demolished to make room for the construction of the parking garage. Asbestos abatement will be required during the demolition in phase B-1 as well. |

||||||||||||||||||

Structural System: (includes aspects of structural steel frame, cast-in-place concrete, and masonry |

The foundation is designed for an allowable bearing capacity of 6000 psf. Due to poor soil conditions, areas of the foundation are supported with geopier rammed aggregate soil reinforcements. A machine, similar to a caisson drilling rig, bores holes into the soil and then packs crushed stone, in thin lifts, into the cavity to provide a solid base for the footing that rests on top of the geopier. A continuous footing system, 16 inches in depth, supports the extensive lengths of exterior and interior CMU walls. Spread footings distribute the loads from the steel columns. A series of grade beams and braces tie between the spread footings. The classroom towers are three story, steel moment frame structures. The beams and girders are a wide range of ASTM A992 wide flange sizes and the columns range anywhere from ASTM A992 wide flange shapes (W) to ASTM A500 rectangle and round hollow structural shapes (HSS). The 4000 psi, cast-in-place, elevated concrete slabs are typically 4-1/2 inches thick over 1-1/2 inch – 18 gage composite galvanized floor deck that spans the beams. The concrete will be pumped to the areas where concrete is being poured. The k series open web steel joists bear on the beams which transfer the roof loads from the various specified metal roof decking to the columns. A 50 ton, mobile all-terrain crane was utilized by the steel erector. The mobile crane was primarily set in locations between the two classroom towers. The East wing of T.C. Williams and the rooms at the South end of the classroom towers are single level, multi height spaces. Load bearing CMU walls, of varying thicknesses, run around the perimeter of the auditorium, gymnasiums, exterior of the East (technology) wing, and South wall of the school. Beam pockets in the CMU provide a bearing surface for the W-shape beams while the majority of the k series roof joists are tied into bond beams at the top of the CMU load bearing walls. The loads in these areas of the structure are transferred to the continuous footing. Classification of Building Category / Use Group: II Codes: 2000 VUSBC |

||||||||||||||||||

| Pre-cast Concrete: | An architectural pre-cast concrete ribbon runs around the majority of the building’s perimeter and below various window units. The east and west sides of the facility contain architectural pre-cast concrete coping. |

||||||||||||||||||

| Mechanical System: | Seventeen rooftop air handling units, ranging from 1,400 to 23,295 cfm, supply conditioned air to the majority of the spaces and employ the use of enthalpy wheels to recover total energy. Supply air entering the gymnasium, auto services, and building trades / construction technology spaces passes through reheat coils. Four additional indoor air handling units control the air in the auxiliary gymnasium, east and west commons areas and the remaining spaces in the East (technology) wing. The variable air volume (VAV) system utilizes 305 terminal units; most of them are equipped with reheating coils which are only activated when the minimum amount of supply air is being forced into a space. A four pipe system supplies and returns hot and chilled water to and from twelve fan coil units that locally returns and supplies conditioned air. In addition, a water unit heater and an electric unit heater service the mechanical and equipment rooms respectively. A direct gas heating, make-up unit in the kitchen activates when the demand arises due to the large quantities of room air that are exhausted through the hoods. The variable flow, hot and chilled water plant is driven by variable speed control pumps. Four natural gas-fired condensing boilers, with capacities of 1.68 million BTUH, heat water from 120oF to 160oF. Water is cooled to 38oF by two, 600 ton water cooled, electric driven centrifugal chillers. Two 750 ton cooling towers condense the R-123 refrigerant so that it can be re-circulated through the chillers which will accept the heat from the systems chilled water lines. The mechanical contractor brought in a 100 ton mobile, all-terrain crane for a duration of two days to set the mechanical equipment. A five zone, wet pipe sprinkler system services T.C. Williams High School. Each zone covers 49,855 to 51,000 sq. ft. A 100 hp vertical in-line fire pump produces a flow rate of 1,000 GPM with a total head pressure of 120 psi. A mixture of sidewall and pendant sprinkler heads will service the spaces while concealed heads are required in all the stairwells. Required Codes: NFPA 13 |

||||||||||||||||||

| Electrical System: | A 480 Y / 277, 3 phase, 4 wire primary feed services the building. Two main 4000 ampere, 3 phase switchboards distribute the required power to the electrical loads throughout the building. Separate switchboards for the chiller units are feed directly from the utility service. The life safety system is backed up by two 800kW, 480V, 3 phase 60 Hz, diesel fueled generators. |

||||||||||||||||||

| Masonry: | The majority of the exterior wall system is face brick with CMU backing. The interior partition walls are primarily constructed of CMU as well. The masons utilize two scaffold systems which include a standard Mason King tube and coupling scaffold and a jacking platform system that mechanically raises and lowers to facilitate the laying of block and brick. |

||||||||||||||||||

| Curtain Wall: | The court is enclosed in a pre-finished aluminum curtain wall system. Aluminum curtain wall units also span from the majority of second floor to first floor window openings of the classroom towers. The units are hoisted into place via a crane and secured on the floor levels to transfer the applied loads through the structural steel frame. |

||||||||||||||||||

Support of Excavation: |

Since the building was designed as a slab on grade structure and the site was relatively level, no significant excavation was performed that required additional support systems to be implemented. Permanent retaining walls were constructed at the south east corner of the site. Shot-Crete was sprayed onto the reinforcing rebar cage to minimize the amount of formwork required on site. |