Technical Assignments

Technical Assignment 1 : Construction Project Management

Executive Summary

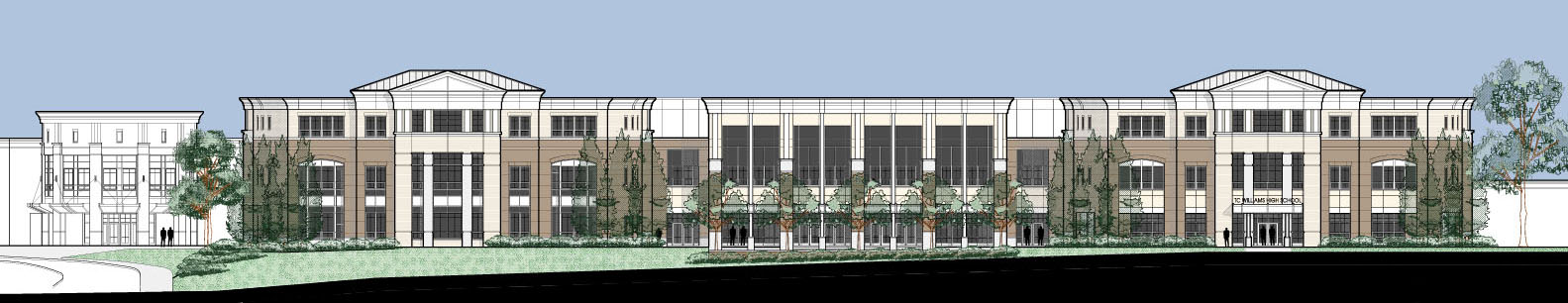

Technical assignment #1 provides an understanding into the building systems and project management of the T.C. Williams High School Replacement Project in Alexandria, Virginia. The unique style of project delivery method employed on this project was designed to reduce the risk to the owner. An advanced form of scheduling, the SIPS (short interval production schedule), aims at managing project resources to capitalize on redundant working procedures and deliver the project as efficiently as possible.

The home new of the Titans will provide its students with new amenities to facilitate their learning. The T.C. Williams High School is seeking LEED ‘Certified’ certification and employs some unique procedures and systems to achieve this goal. Students will be exposed to a permanent measurement and verification system that monitors the facilities water and energy usage and displays the data on a control console in the commons court area. A roof garden provides students with a living laboratory while naturally filtering the rainwater. A 450,000 gallon cistern system will collect the rainwater from the structures immense roof area to service non-potable systems such as the toilets, air conditioning units, and irrigation. The uniqueness of this project expresses the owner’s determination to build a sustainable facility while reducing its impact on the environment.

Technical Assignment #1 (.pdf)

Technical Assignment 2 : Cost and Methods Analysis

Executive Summary

Technical Assignment #2 delves into the cost and methods for the construction of the T.C. Williams High School building systems. The detailed project schedule reveals a 37 month duration from project start-up and initial interim classroom mobilization in August of 2004 through the final completion of the high school facility in July of 2007. After analyzing the schedule activities for the construction of the superstructure, a clear progression of work flow was revealed and has been presented in the technical report. The strategic planning of the site logistics attempts to minimize the complications and delays that arise from site congestion.

An assemblies estimate addresses the cost of the mechanical systems that supply air to 445,370 square feet of conditioned spaces. R.S. Means was referenced to generate the $6,302,000 estimate for the multiple and single zone air handling units along with the system of fan coil units. The quantity takeoff of the structural steel members, designed for the construction of the high school, uncovers a complex assemblage of various steel shapes and sizes that increases the potential of construction errors and delays. In order to prevent construction delays, a heightened level of management is required to organize the erection of the structural steel. If the erectors do not have access to the appropriate members during the sequence of erection, the activity experiences delays. The general conditions estimate incorporates the project duration with the staffing plan of the general contractor and the application of site specific requirements, established through the site layout planning, to generate a cost for materials, equipment, and labor accrued by the GC. At 7.46% of the overall project cost, the general condition costs were estimated at $6,710,508.

Technical Assignment #2 (.pdf)

Technical Assignment 3 : Alternative Methods and Research

Executive Summary

Technical Assignment #3 is designed to generate ideas and develop the proposal for the technical analysis and research performed during the Spring semester. After participating in the 2006 PACE Roundtable event in the fall, a comprehensive list of critical industry issues discussed at the even was written in order to formulate connections to the construction of the T.C. Williams High School Replacement Project.

Acquiring an interest in virtual design, the decision was made to develop a Building Information Model of the T.C. Williams High School and research its effectiveness in value engineering, work sequencing, and site logistics practices. Further research into the unique form of design-build delivery method, utilized on the T.C. Williams High School project, will uncover the risks and advantages to the contracted parties for delivering a project in this manner. The feasibility of employing BIM software on the project will also be assessed.

After revisiting my analysis of the project to date, several areas were identified that had the potential for further investigation into the implementation of alternative construction approaches to the design, planning, and construction of the high school facility. To promote the acceptance of BIM among practitioners in the construction industry, the model will be used to perform and illustrate the technical analyses, revealing a few of the advantages that modeling software has to offer.

The main focus of the analyses will be based on the research and selection of alternative building materials to the durable, yet less than aesthetically pleasing, Concrete Masonry Units [CMU]. The installation of CMU is extremely labor and time intensive and T.C. Williams has an extensive quantity of CMU load bearing and partition walls. Research will focus on the cost, schedule, and performance of the alternative materials in comparison to CMU. The remaining analyses carry the implementation of the alternative materials into the analysis and redesign of the auditorium acoustics and sequencing of schedule activities to promote less congested site conditions.

Technical Assignment #3 (.pdf)