Northwest Exterior Perspective

Northwest Exterior PerspectiveNew Science Building - Phase 1 Addition

Location: Buffalo State College Campus| 1300 Elmwood Avenue| Buffalo, NY 14222

Building Occupant: Buffalo State College Science and Math Departments

Occupancy Type: Education

Size: 96,000 sq. ft. (Phase 1 Addition)

Stories: 3 above grade|penthouse|basement

Dates of Construction: October 15, 2009 - March 12, 2012

Cost: $34,807,000

Project Delivery Method: Design-Bid-Build

Project Team

Owner

Buffalo State College/

State University Construction FundContstruction Manager

Architect

MEP

Wind/Snow Consultant

Commissioning Agent

Architecture

Codes:

IBC 2006

NEC 2008

Building Code of NYS 2007

New York State Energy Conservation Construction Code

Plumbing Code of NYS

Mechanical Code of NYS

Fuel Gas Code of NYS

SUCF Directives

ASCE 7-02

AISC 301, 303.1, 303-05

ACI 318-02

ANSI C2 – National Electrical Safety Code

NFPAZoning: Buffalo State College as an educational institution does not fall under City of Buffalo R-2 zoning requirements.

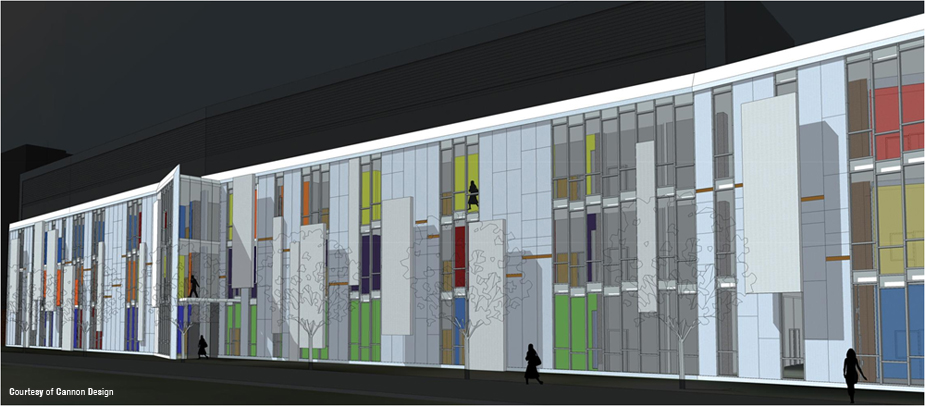

Historical Requirements: Not ApplicableThe Science Building at Buffalo State College houses labs, offices, and classrooms for the school’s natural science departments. The building exterior conveys the interior scientific inquiry and development through the materials and design. A high-tech appearance is achieved through numerous design features that cleverly express themes associated with the various science departments including: optics, geology, genetics, biology, and math.

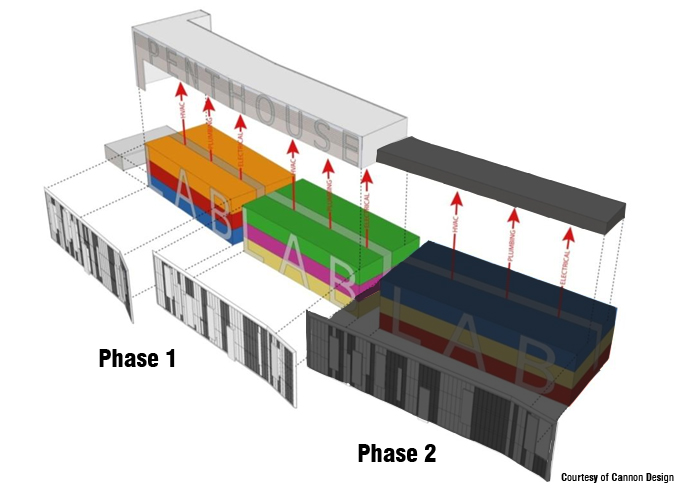

The Phase 1 building project is an addition to the existing science complex and joins to the existing building via an atrium. The linear plan is broken on the western side with a vertex in the middle and two curtain wall segments that are slightly angled. Building utilities feed up through the central spine of the building to the penthouse and will be fed into the renovated Science II building in Phase 2.

A combination of genetics and mathematics is portrayed in the arrangement and proportions of the glass and metal panels on the western curtain wall. Brightly colored walls are visible behind the glass panels of the western corridor to mimic the refraction of a prism. Throughout the building, striations, platforms and the linear atrium space refer to geologic forms such as mesas and gorges for proportions. Building circulation takes a cue from biology and creates a main thoroughfare through the atrium space to connect the academic and residential areas of campus. Additionally, the science curriculum is fostered by an environment that supports collaboration. Throughout the building there are gathering spaces for students with writable surfaces. Optimum floor space and flexibility is enabled by the concrete structural system and central utility spine.

Building Enclosure

The walls of the building are a combination of concrete masonry unit assemblies and curtain wall, both using cold metal framing to hang exterior paneling. The western façade uses cold metal framing and a combination of aluminum composite metal wall panels and high performance, insulated glazing. The very top level, the mechanical penthouse, is a shell composed of non-insulated metal panels.

The atrium permits natural light through a series of thirteen sloped glazing assembly skyights and clerestories, with condensation resistance and a solar heat gain coefficient ≤ 0.40. Roof structure is predominantly concrete deck except for the steel roof deck on the penthouse. Roofing layers are similar on each roof type with either a tapered or flat insulation (R-20), membrane underlayment board, and light-colored EPDM (ethylene propylene diene terpolymer) roof membrane.

Western Facade

Sustainability Features

The building design is required to satisfy LEED Silver certification and is designed for LEED Gold. Sustainability features are largely attributed to controls for the mechanical and electrical systems. Mechanical system design incorporates variable speed drive motors for air handling pumps and fans to increase efficiency. The lighting systems incorporate automatic lighting controls with occupancy and daylight sensors.

Daylight infiltration is enhanced on the western side of the building, such that light passing through exterior glazing and through the corridor reaches several offices by interior windows. Vertical shades and curtain wall projections, however, prevent issues with glare.

The project will satisfy numerous LEED points from the beginning of construction, with strategies such as Construction IAQ Management, to completion with initial building performance being tested by a commissioning agent.Construction

The Phase 1 addition for the Buffalo State College (BSC) Science Building is scheduled for October 15, 2009 – March 12, 2012. Phase 2 renovations (which would bring total complex area up to 224,000 ft2) are projected to finish in 2015.

Site work throughout demolition and construction is to uphold standards set forth in the NY Guidelines for Urban Erosion and Sediment Control. Construction methods include plans for temporary mechanical services to the existing building following demolition, which comply with the IAQ management plan. Of all waste generated throughout construction, 50% (by weight) is to be salvaged or recycled and documented with progress reports submitted regularly.Electrical

Medium voltage service enters the building at 5kV and is routed to a unit substation within the building. The double-ended 4.16kV 480Y/277 V 3φ 4W substation is located in the basement, feeding a 2,000A 208V/120V 3φ 4W switchboard in the basement and a 3,000A 480Y/277 V 3φ 4W switchboard situated in the penthouse. The basement switchboard feeds the normal power in the basement and a 1,000A 208V 3φ 4W bus duct serving laboratory loads on normal power throughout the building and future phase. The penthouse switchboard serves most of the mechanical equipment.

The building is served by four separate, switched branches: Normal, Emergency, Standby, and Optional. The emergency branch of the distribution system is served by a 800 kW diesel-driven generator enclosed in a separate room in the basement.Lighting

General lighting within the building is supplied by linear fluorescent luminaires using T8 or T5 lamps predominantly at 277V. Classrooms and labs utilize pendant, direct/indirect linear fluorescent luminaires to provide even luminance levels across task planes while minimizing shadows. This is important due to the measuring and reading tasks that occur within the space. Corridors in the atrium combine a recessed wall-mounted fixture (switched for emergency power) as well as a decorative, compact fluorescent pendant. The atrium combines daylighting by means of clerestories and skylights with supplementary electric light from pendant, wall-washing, metal halide fixtures that illuminate the acoustical ceiling panels at the top of the space.

Mechanical

Heating for the Science Building is provided by a 10” 40 PSI metered steam supply connected to the campus system and distributed by redundant variable flow pumps. AHU preheat coils are energized by low pressure 15 PSI steam.

General cooling is supplied by a high efficiency, water-cooled, electric centrifugal chiller in the penthouse. The penthouse also houses the refrigerant monitoring and exhaust system. Primary/secondary pumping connects the chiller to the AHUs and heat is rejected by two induced draft cooling towers in the penthouse. Data rooms are also served by a back-up DX system while the main telecom room is served by a 10 ton split-system a/c unit.

Three AHUs supply 100% outside air to the labs and provide partial redundancy since they are sized to approximately 50% peak airflow. One AHU is connected to emergency power to prevent excessive negative pressurization. Each lab area has one dedicated VAV terminal unit with a hot water reheat coil and low velocity supply diffusers. The atrium has one mixed air VAV AHU with enthalpy control and outside air flow measuring. An array of nine 3,500 cfm fans is also dedicated to air handling in the atrium.Structural

The majority of the Science Building is composed of a cast-in-place concrete system with steel framing in connecting areas such as the atrium, the northeastern entrance, links to the existing building, and the mechanical penthouse. The foundation consists mainly of an H pile and cap (4’ thick typically) system supporting the interior spaces, spread footings for the atrium, and several strip footings along the exterior walls.

The basement structural slab is 10” thick and supported by 2’ square grade beams on the west, exterior edge of the building. The first level is a 5” thick, one-way concrete slab spanning north to south, primarily supported by concrete beams B4 24x30. The second and third levels are 8-1/2” one-way concrete slab supported by B1 24x30 beams, which are tapered and cantilevered into the atrium and west, exterior edge of the building. The cantilevers on the western edge of the building support the corridors and the metal and glass panel curtain wall.

Steel framing in the atrium consists of HSS10x.625 columns with a 21’-0” span. HSS8-5/8x.250 columns support the northeastern entrance. Atrium and penthouse framing consists of wide flange beams, primarily W12x14 and W18x50 respectively.Fire Protection

Most areas within the building are protected by a wet sprinkler system except for rooms housing extensive electrical, voice, or data equipment which have a partition that is rated at least three hours. The fire command center is located in room 127 and houses the Fire Alarm Control Unit (FACU), Emergency Voice/Alarm Communication (EVAC), Graphic Smoke Control Panel (GSCP), and annunciator panels for the generator and elevators. Alarms are ADA compliant combined speaker/strobe.

Atrium fire protection consists of 175° sidewall sprinklers in the skylight and 135° dry pendant sprinklers in between skylights on the ceiling, as well as a manual smoke exhaust operation controlled by the GSCP. Elevator shafts contain sidewall sprinkler heads.Transportation

There are three passenger elevators in the Science Building addition, one adjacent to the north stairwell and two in the southwest corridor. The electric traction elevators specified are based on Otis Gen2 Machine Room-Less Elevators and are rated for 2500 lbs. The elevators are connected to the fire protection system for automatic recall and are also operable on standby power. The elevator controllers and ATS are located in the basement areaway.

Telecommunications

The telecom service entrance room is connected to campus utilities by interbuilding, exterior fiber optic cabling. Individual telecom rooms are connected by intrabuilding backbone systems with 24 strand 50 micron cabling in 4” electrical metallic tubing (EMT) conduit. Horizontal cabling throughout the building telecom distribution system is copper. Telephone service for the existing building and addition is being updated from a Centrex phone system to VoIP.

Data outlets are available above counters in the lab spaces and throughout other work spaces. Within the lab furniture, 2” conduit is stubbed up for data and terminated in a furniture doghouse. The labs and offices also have electronic card reader door systems for security. Wireless access points are available in the labs and throughout most of the corridors.

Note: While great efforts have been taken to provide accurate and complete information on the pages of CPEP, please be aware that the information contained herewith is considered a work‐in‐progress for this thesis project. Modifications and changes related to the original building designs and construction methodologies for this senior thesis project are solely the interpretation of Marie Ostrowski. Changes and discrepancies in no way imply that the original design contained errors or was flawed. Differing assumptions, code references, requirements, and methodologies have been incorporated into this thesis project; therefore, investigation results may vary from the original design.

Senior Thesis Main Page | Penn State | Architectural Engineering | AE Computer Labs | Contact: mso139@psu.edu

| This page was last updated on 10/12/2009, by Marie Ostrowski and is hosted by the AE Department ©2009 |

|---|