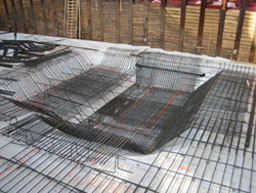

Foundation Bottom Bars - March 8, 2006

Foundation Bottom Bars - March 8, 2006 |

Foundation Reinforcing - March 24, 2006

Foundation Reinforcing - March 24, 2006 |

Progress - June 20, 2006

Progress - June 20, 2006 |

Progress - June 29, 2006

Progress - June 29, 2006

|

|

Progress - August 2, 2006 |

Second Floor Transfer Beam - May 23, 2006

|

Penthouse Structure - August 29, 2006

(44'-0" Span between shear wall support and column support

|

|

|

Building Name:

Location and Site:

Occupant:

Occupancy Type:

Size:

Number of Stories:

Dates of Construction:

Project Delivery Method:

Contract Type:

Project Cost: |

40 Bond

40 Bond Street

New York, NY

Confidential

Residential

90,000 SF

10 Stories + Penthouse (1 cellar)

December 2005 - Summer 2007

Design - Bid - Build

Guaranteed Maximum Price

$40 Million

|

Owner:

Architect of Record:

Design Architect:

Structural Engineer:

Facade Engineer:

Facade Consultant:

MEP:

Geotechnical/Environmental

Engineers:

Vertical Transportation:

Lighting Designer:

Low Voltage Designer:

Acoustic Consultant:

Construction Manager:

Construction Consultant:

|

Confidential

Handel Architects LLP

105 Varick Street, 8th Floor

New York, NY 10013

Herzog & de Meuron

Rheinschanze 6

CH-4056 Basel

DeSimone Consulting Engineers

18 West 18th Street, 10th Floor

New York, NY 10011

Dewhurst Macfarlane & Partners

45 East 20th Street

New York, NY 10003

Israel Berger & Associates

232 Madison Avenue

New York, NY 10016

Ambrosino DePinto & Schmieder

275 Seventh Avenue

New York, NY 10001

Langan Engineering & Environmental Services

21 Penn Plaza

260 West 31st Street Suite 900

New York, NY 10001

Lerch, Bates & Associates

20 Jersey Avenue

Metuchen, NJ 08840

Johnson Schwinghammer

335 West 38th Street

New York, NY 10018

Electronic Security & Communications Corp.

149 Madison Avenue

New York, NY 10018

Shen Milsom & Wilke, Inc.

417 Fifth Avenue

New York, NY 10016

Bovis Lend Lease, Inc.

200 Park Avenue

New York, NY 10166

Ryder Construction, Inc.

519 Eighth Avenue

New York, NY 10018

|

Located in the NoHo (North of Houston Street) neighborhood of Manhattan, 40 Bond Street is an iconic piece of architecture intertwined with an equally interesting structure. The idea behind this project is a reinvention of the cast iron building typology that is prevalent in this area of New York City. The site, which was previously a parking lot, now houses a beautiful residential building that echoes the surrounding neighborhood in style with a modern twist. Within the cellar is a fitness center and storage space along with mechanical and electrical rooms. There are five through-building, 2-level townhouses located on the ground floor, which are the first townhouses to be built in the city for decades. These townhouses all have private entrances off Bond Street and gardens located at the rear side of the building. Each of the floors between level three and level six contains four condominiums units, while those located on levels seven through nine have two condominium units per floor. These units have 11’-0” ceiling heights made possible by the concrete structure and fully operable floor-to-ceiling windows. Also, at the seventh floor there is a 20’-0” setback that allows for a landscaped roof garden terrace. A full-floor condominium occupies the tenth floor with a penthouse structure rising 20’-0” above the main roof line. This grand space has 14’-0” ceilings and appears to span 44’-0” with no supports allowing for an indescribable view of the city. This area is also surrounded by a roof terrace with glass walls separating the interior and exterior environments.

These luxury apartments allow residents to enjoy the services and amenities offered to those staying in five-star hotels. The finishes used throughout the building are also reminiscent of this type of lifestyle. The entrance lobby makes use of Vulcano engineered hardwood flooring and Corian carved with custom patterns and white gloss finish on the walls. The ceiling of the lobby is mirror stainless steel with an embossed pattern on the exterior and interior. The apartments contain Vulcano engineered hardwood floors and marble mosaic is used in the bathrooms for the flooring and wall finish. There are also precast concrete pavers with custom patterns used on the roof terraces.

One of the most stunning aspects of this structure is the building envelope. The main roof is made up of a typical structural slab, fluid applied membrane, protection sheet, 4" rigid insulation, gravel ballast and cast iron drains. The pavers mentioned above are present on the roof terrace of the seventh floor while the terrace surrounding the penthouse is a combination of pavers and wood decking. The real interesting roof structure is then found above the penthouse. Upturned beams and inclined piers span with a roof slab that allows the area below to achieve a 44’-0” support-free space. These members tie into hidden columns and the core shear wall allowing nearly three unobstructed glass walls to enclose the area.

40 Bond Street is attached on both its east and west faces. The north and south side then display two distinct facades. Along cobble-stoned Bond Street there are 5' x10' tilt-and-turn operable aluminum windows tinted to meet the necessary shading coefficient surrounded by bell-shaped green glass mullions. The Crisunid Cridecor curved glass produced by Cricursa in Barcelona is a combination of 5mm thick green glass laminated to 5mm thick clear glass. The mullions have a gray and green ceramic frit pattern on the edges of the bell to cover the frame but eventually lead to translucent glass at the apex. Below this layer of glass are No. 8 mirror stainless steel plate covers that allow for interesting reflections of the surrounding neighborhood. A rain screen of aluminum frames is also a part of the window assembly. This complicated façade was put in place by ornamental ironworkers and the fine craftsmanship is clearly seen. The north face employs the same windows but the material used for the mullions is replaced with pre-patina copper. Over time this material will develop a green patina and be closer in color to its parallel face.

Another distinct feature of 40 Bond is the cast aluminum gate that spans 140’-0” in length and 22’-0” in height. Engineered for stability and able to conceal its hardware, this gate is a controlled chaos modeled after graffiti patterns seen throughout the city. It is not only an intricate design but also serves the purpose of providing a sense of security and privacy for the townhouses located on the ground floor. Together with the completely glass façade, 40 Bond Street’s presence interacts with the neighboring context while clearly making an architectural statement. |

The major codes used on this project include:

New York City Building Code (2003)

New York City Electrical Code (1999 NEC amended for NYC)

New York State Energy Conservation Code (2002)

40 Bond Street is located in the M1-5B zoning district. This classification is a special mixed use district with a combination of guidelines from the residential R5B district and amendments and alterations to satisfy the distinct requirements for mixed use areas.

|

|

| Primary Engineering Systems |

|

CONSTRUCTION

Excavation for 40 Bond began in November 2005 and substantial completion took place in Summer 2007. The project delivery method was design-bid-build with a Guaranteed Maximum Price (GMP) contract. The final cost totaled $40 million. The construction manager on the project was Bovis Lend Lease, Inc. with Ryder Construction, Inc. as the construction consultant.

Special construction methods were needed to install the glass façade on the south face which was done by ornamental ironworkers.

ELECTRICAL/LIGHTING

The electrical service to the building is a 120/208V 3 phase 4 wire system including an emergency system, all provided by Consolidated Edison in Manhattan. The common residential distribution switchboard is 120/208V 3 phase 4 wire with a 2000A bus in the cellar. Each residential unit then has its own panel. There are also five additional panels for the mechanical rooms, elevator function, the lobby and fitness center.

There is a variety of lighting used throughout this building. Some included are soft white incandescent, clear halogen, fluorescent and HID. There is also a dimming system that ties into the low-voltage controls.

MECHANICAL

There are two air handling units located in the cellar that range from 1100 to 2000 cfm to control the heating and ventilation in the lobby and corridor spaces. Also, in the cellar there are two boilers that serve the purpose of heating the remainder of the building, various water source heat pumps, expansion tanks and a shell and tube heat exchanger. On the roof there is a CMU penthouse structure with a natural gas-fired make-up air unit with airflow of 2550 cfm, numerous fans, a draft inducer and a 150 ton, 35,265 cfm cooling tower servicing the condenser water system.

STRUCTURAL

40 Bond employs a concrete structure that allows for maximum floor-to-ceiling height, serves as an acoustical barrier, and permitted the design of the penthouse structure. The foundation consists of a 30” thick mat foundation with a compressive concrete strength (f’c) equal to 5000 psi normal weight concrete. The remaining floors are 9” thick flat plate slabs with f’c=5950 psi from Floor 1 to Floor 3 and f’c=5000 psi from Floor 4 to the penthouse. A slab drop is provided on the ground floor for the townhouse entrances and typical slab depressions are present for toilet rooms and fireplace installation. The typical bays range in size from 19’-6” x 25’-0” to 23’-2 ½” x 25’-0” which allows for two-way slab action.

The lateral system is a combination of 12” ordinary reinforced concrete shear walls. There is one shear wall located on the west face of 40 Bond and two other walls constructing a core within the building. All shear walls supporting the ground floor to those supporting the fourth floor have concrete with f’c = 8000 psi while those supporting the rest of the building have an f’c = 5000 psi. .

10”x10” perimeter columns are located at 6’-3” on center so that they may be hidden by the glass mullions on the south façade and copper mullions on the north façade. Interior columns are a variety of sizes ranging from 12”x36” to 16”x58”. Most are either square or rectangular, but within certain condominiums there are 22” diameter columns that transition to 22”x22” above and below based on the occupant’s desire. All columns from the basement to those supporting the fourth floor have a concrete compressive strength f’c=8000 psi, while those above have a strength f’c=5000 ksi.

Because the floor system is a flat plate slab there are a limited number of beams within the structure of 40 Bond. Those beams that are included are spandrel beams on the east and west face, beams around the townhouse stairs and several transfer beams. All the transfer beams have an f’c=10000 psi and range in size from 20”x24” at the seventh floor setback to 60”x16 at the third floor when the small 10”x10” columns transfer to long, slender columns below.

Finally, there is the penthouse structure that allows for a 44’-0” clear span with the assistance of a roof slab, upturned beams, and inclined piers. They allow not only for the clear span but also 14’-0” ceiling heights. The only two supports are two 28”x16” columns that are hidden within the fireplace and a core shear wall, resulting in nearly three glass walls.

|

| Engineering Support Systems |

|

FIRE PROTECTION

Water service is accessible from the Siamese connection at the southeast corner of the building on Bond Street. There is an automatic fire pump with 500 gpm flow, 95 psi (220) feet head, 3600 rpm, and 40 HP controlled by a 208V 3 phase system. There is also a vertically mounted jockey pump with 15 gpm flow, 278’ head, and 5 HP with the same 208V 3 phase system. Both pumps are located in the cellar. Automatic sprinklers were installed throughout the entire building based on light hazard occupancy. Also, all centralized stairwells and elevator shafts are 2 hour rated.

TRANSPORTATION

Two sets of stairs and two elevator cabs are located in the core of the building enclosed by the 12” shear walls; all of which continue from the cellar up to the tenth floor. There are stairs within the townhouses as well that allow transportation between the first and second floor of these units. The core does not have opening to the second floor because the access is limited to only those in the townhouse units. There is also a staircase from the tenth floor up to the penthouse. The elevators have 2500 lb capacity with a speed of 350 fpm.

LOW VOLTAGE

The low-voltage system controls the telecommunication, security and access technologies within the building. The telecommunication processor is located in the phone data room in the cellar. There is also an intercom system, card access controls, and alarm system. All units, including the townhouses, also have Crestron electronics that manage the HVAC thermostat, audio/visual equipment, and lighting. |

|