Building Statistics

General Building Data

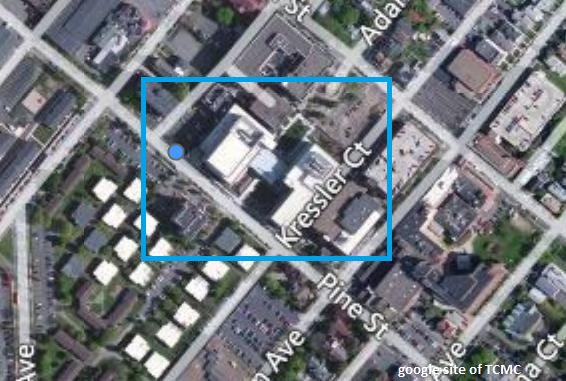

The Commonwealth Medical College (TCMC) is located at 525 Pine St, Scranton, PA. The building is used as a medical school so students and faculty members will be the main occupants. The total size of the project is 209,000 square foot, covering up to three acres of prime space in the heart of the city of Scranton. The builiding is five stories high, including the penthouse, and up to 93 feet tall. TCMC began its construction on May 2009 and ended on Oct 2011. The final cost of the entire project is estimated to be $120 million. TCMC is a Design-BId-Build project method.

Primary Project Team

Owner: The Commonwealth Medical College

General Contractor: No General Contractor is involved.

Construction Management: Quandel Construction Group

Architects: Highland Associates and HOK

Engineers: Highland Associates for M.E.P. and Structural Engineering

Interior Design: Highland Associates and HOK

Landscrape Architect: McLane Associates

Architecture

“The Commonwealth Medical College (TCMC) is a freestanding, independent medical school with no university affiliation. This unique structure allows it to partner with different health science programs. Graduates are credentialed, community physicians trained in evidence-based medicine.” Stated by HOK. TCMC is clad in brick, stone, and glass curtain wall. The building is separated into two individual wings, west wing and east wing. The link is the lobby area that connects the two wings and it is clad largely in insulated glass units to let natural sunlight in. An additional feature is the tower which is also clad largely in glass. The tower, located in the East wing, is considered the main focal point of the building. The interior space of the tower is mainly corridors and small meeting rooms so the students can enjoy the view. TCMC also has a garden around the link that allows the occupants to enjoy the nice green views that the city cannot offer.

Zoning Requirements

The major building model code involved is the IBC 2006. TCMC is zoned for business (B), assembly (A-2, A-3), mercantile (M), Storage (S-2), and industrial (F-2). Since TCMC is a new buildng with modern technology, there is no historical value to the building.

Major Design Codes

2006 International Building Code (IBC)

2006 International Mechanical Code

2005 NFPA 70/ Nation Electrical Code

2006 International Plumbing Code

2006 International Fuel Gas Code

2006 International fire Code

Building Enclosure

The enclosure of TCMC is made mostly of brick and glass facade. Honeycombed transom glazing are used. TCMC has a composite steel framed system. The existing floor system is held up by W-shaped steel columns and composite steel beams. The floor slab in the West wing is a composite steel deck with a 4.5" normal weight concrete topping on a 3" lok-floor 20 gauge galvanized composite floor deck, giving it a total slab construction of 7.5". The East wing, and the link, are 3.25" lightweight concrete topping on U.S.D. 2" lok-floor 20 gauge galvanized composite floor deck, making the total thickness of 5.25".The main roof is constructed of 1.5" type B wide rib, 22 gauge, painted roof deck supported by W-shape framing. EPDM memberane over R26 insulation are used for the roof system.

Sustainability Features

TCMC is committed to energy and resource efficiency. The building is currently seeking for a silver status with LEED. Sustainable design strategies in TCMC include, but not limited to, rainwater collection for the gardens, indigenous landscape material, a heat recovery system, carbon dioxide and occupancy sensors, high performance glazing, integrated daylight control through honeycombed transom glazing, and the use of local stone.

Structural System

Foundation: The West wing of the TCMC is built with a mat slab foundation that is 4'-0" thick. The mat slab is designed for a soil bearing pressure of 3000psf. It is on top of a 2'-0" thick structural fill and a 4" mud slab. After the mat slab, over 4' of compacted AASHTO # 57 stone typical was placed in followed by a 5" slab on grade. The East wing of the TCMC has drilled caissons ranging from 36" to 60" in diameter and is used to carry loads from grade beams to bedrock below. The typical floor slab in the east wing is 7.5" and it's also on top of compacted AASHTO material.

Framing: TCMC has a composite steel framed system. The sizes of the beams and columns ranged from W8x24, being the lightest, to W14x257, being the heaviest. The longest column is 44'-7" and it stopped between the third and fourth floor. An additional 48'-0" of lighter steel column is connected to this column, extending it all the way up to the penthouse.

Lateral System: The main lateral system used in TCMC consists of fifteen moment frames. They are present in the west wing, east wing, and also in the link. Most frames are near the exterior wall to maximize the lateral force it can resist. The moment frames span across the entire building, from north to south and from east to west. This provides lateral resistance in each direction. The frames in the link begin on the first floor and extend to the roof, the third floor. The frames in the two wings begin on the first floor and extend to the floor of the penthouse.

Mechanical System

The mechanical systems present in TCMC are air handling units, lab exhaust system, refrigeration, and a heating plant. The west wing air handling units are between 15,000 to 70,000 cfm. The East wing air handling units are between 19,000 to 50,000 cfm. Air handling units include heat recovery coils, MERV 8 prefilter banks, air blenders, preheat coils, cooling coils, Greenheck plenum type supply and return fan arrays, sound attenuators and humidification modules. The units were utilized with overhead Variable Air Volume (VAV) air distribution delivery.

A bank of five 20,000 cfm Strobic fans with prefilter, heat recovery coils, and SMART control system was provided for the laboratory exhaust system.

As for refrigeration, four 300 ton MCQuay magnetic bearing chillers with harmonic filters and cold-water startup head pressure controls and valves were provided for central cooling. Three cooling towers, 800 ton capacity each, bottom fed with bottom equalizer, supply and return and heat traced above the roof. A 300 gpm free-cooling plate frame heat exchanger and VFD driven pumps were incorporated into the system design for free cooling in the tele/data, electric room, and utility fan coils.

For part of the heating plant, three 80 psig 100 bohp Fulton high pressure steam boilers was provided for sterilization, cage wash, and humidification. One 300 bohp Bryan flexible watertube boiler and six 50 bohp Hydrotherm KN-20 condensing cast iron boilers were provided. All boilers for humidification and building heat including pumps, main switchgear, incoming water and fire services and emergency generation were located in this building. The main lobby was provided with a radiant slab heating system.

Lighting/Electrical System

TCMC contains both 208Y/120 Volt and 480Y/277 Volt, 3-Phase electrical system that powers the entire building. There are electrical rooms in each wing where the wiring is coming off from. Receptacles run on 208Y/120 volt 3-Phase. Mainly fluorescent lightings that are motion-sensor are used throughout the building. Additionally, some LEDs are used. Fluorescent fixtures are used in offices, classrooms, hallways, labs, and lecture rooms. LED fixtures are used mostly in the atrium and large lobby areas. When designing, it was kept in mind to bring in natural lighting into the main atrium.

Fire Protection

TCMC complies with the 2006 International Fire Code for fire prevention. The building is equipped with a sprinkler and standpipe systems, fire extinguishers, and fire department connection. Additionally, all structural elements, such as columns, girders, and trusses, have at least a 2-hour fire rating. This was achieved by spray fireproofing. The floor construction, including beams, also has a 2-hour fire rating due to the composite construction and concrete thickness. Fire barriers used throughout the building have 2-hour fire rating.

Transportation

TCMC has one bank of elevator and two stair towers in each wing. These provide access to all four floors of the building, and the roof or the penthouse. In the West wing, the stair towers are located on the north and south of the building. In the East wing, the stair towers are located in the center and the south end of the building. All access to vertical transportation is available to all occupants in the building.

Construction

The Commonwealth Medical College began construction in May 2009 and was completed in Oct 2011, totaling $120 million. It was a design-bid build contract and no general contractor was involved in the project. The biggest challenges on this construction were the coordination required between the MEP systems, along with its sustainability goals. All mechanical equipment had to be handled with care when installing. Quality control was also important in this project to ensure that all windows and glass were placed properly. The details of the building had to be extremely accurate to its design for the price of this project.

Special Systems

In order to provide a high efficient system, all HVAC and lighting systems are controlled mainly by a computerized control system. The intent is to minimize energy consumption. As part of the temperature controls system, an extensive DDC/Electric TAC facility management system was designed for building, lighting, security, temperature, ventilation and environment control.