Building Statistics

General Building Data

Building Name: Pershing Hill Elementary School

Location: 7600 29th Division Road

Fort Meade, MD 20755

Owner/Occupant: Anne Arundel County Public Schools

Function Type: Primary Education

Project Delivery Method: Design-bid-build

Contract type: Multiple Prime

Number of Stories: 2

SqFt: 87,160

Construction Costs: $13,311,664

Estimated Completion: Feb. 2011

Pershing Hill Elementary School Project Team

Owner: Anne Arundel County Public Schools (http://www.aacps.org/)

Architect: Grimm and Parker Architects (http://www.grimmandparker.com/)

Civil Engineer: KCI Technologies, Inc. (http://www.kci.com/)

MEP Engineer: James Posey and Associates (http://www.jamesposey.com/)

Structural Engineer: Columbia Engineering, Inc. (http://www.columbia-engineering.com/)

Fire Protection Engineer: EBL Engineers (http://www.eblengineers.com/)

Construction Manager: Jacobs Project Management Company (http://www.jacobs.com/)

Site Prime Contractor: M. P. Zink Construction

Abatement Prime Contractor: Delaware Cornerstone Builders (http://www.dcbuilders.com/)

Demolition Prime Contractor: Pleasants Construction

Concrete Prime Contractor: Canyon Contracting (http://www.canyoncontracting.net/)

Masonry Prime Contractor: Pompano Masonry (http://www.pompanomasonry.com/)

Steel Prime Contractor: Kinsley Manufacturing (http://www.rkinsley.com/Manufacturing.aspx)

General Works Prime Contractor: Hancock & Albanese, Inc. (http://www.hancockalbanese.com/)

Roofing Prime Contractor: J&K Roofing (http://www.jkroofingllc.com/)

Windows Prime Contractor: Spear Window

Kitchen Equipment Prime Contractor: Singer Equipment (http://www.singerequipment.com/)

Casework Prime Contractor: Steel Products (http://www.steelproductsinc.com/)

Structural Wiring Prime Contractor: Wire Solutions (http://wiresolutionsllc.com/)

Mechanical & Plumbing Prime Contractor: LH Cranston, Inc. (http://www.lhcranston.com)

Fire Protection Prime Contractor: Kennedy Fire Protection (http://www.rwwarner.com/kennedy/)

Electrical Prime Contractor: Key Systems Electrical (http://www.keysystemselectric.com/)

Architecture

Major National Codes:

Structural Code: IBC 2006

Mechanical Code: 2003 IMC with modifications

Electrical Code: 2005 NEC

Plumbing Code: 2003 National Standard Plumbing Code with 2004 Supplement & NFGC

Other Codes: 2006 NFPA 101 Life Safety Code

2006 Maryland Accessibility Code

2006 IECC

Zoning: Pershing Hill Elementary School will follow local zoning codes for buildings used for educational purposes.

Historical Requirements: None

Pershing Hill Elementary school is two stories. The first floor contains the spaces used by all students including: the gymnasium, cafeteria, media center, computer lab, music room, health room (also known as a nurse’s office), principle’s office, and classrooms. The second floor consists primarily of classrooms, but also contains the science room and faculty lounge. Outside of the entrance to the vestibule is a curved aluminum canopy, which is attached to the façade by a one inch hanger pipe assembly attached to embedded plates.

The first floor contains a large block to the North of the main hallway which contains the gymnasium and cafeteria (as well as the supporting facilities for these features. There is a stage in the cafeteria, which allows it to double as an auditorium. For presentations with a larger audience, the partition between the cafeteria and gym can be removed, allowing for additional seating.

The supporting facilities for the gymnasium and cafeteria are placed on the sides of these rooms opposite the main hallway. For the cafeteria this includes the food prep and food storage area, as well as the food serving area which is accessed by two doors on the north side of the cafeteria. By designating one door the entrance and the other as the exit; it is possible to move a large number of children through the food service area, as they do not need to turn around after receiving their food.

On the South side of the main hallway is the media center, which is attached to the computer lab. To the East and West of the media center are two wings which primarily contain classrooms, and closely follow the plan of the second floor wings. Because the entrance is to the West, the base of the west wing also contains the administrative offices. This allows the receptionist to see who is entering and exiting the school, and ensures that any visitors are reminded to sign in.

The second floor consists of two wings and a hallway connecting them. The second floor hallway lies on top of the main hallway on the first floor, but there are no rooms to the north of it. This allows the gymnasium ceiling to rise in order to accommodate basketball games.

Both wings are largely composed of classrooms on either side of the hallway. Four stairwells in total are located at the end of the hallway, as well as where it turns. The teacher’s lounge and resource rooms are stationed between the two wings. The classroom bathrooms are placed along either the North or South wall, and are placed so they share a wall with the bathroom for the adjacent classroom. The classrooms are on both sides of the hallway, and because they are along the wings of the building every classroom is open to natural light.

Building Enclosure

Building Facade

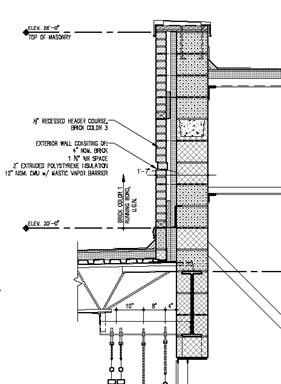

The exterior wall typically consists of a 4” brick veneer, 1¾” air space, 2” of extruded polystyrene insulation, and 8” CMU with a vapor retarder. Veneer ties are placed at a maximum of 16” on center, as are the weep holes. This is the typical system for the exterior walls, although it varies slightly at certain locations and the color of the brick changes throughout the building. The exterior brick comes in three different colors, with a lighter color being used on the second floor, and  a darker decorative band running along the top of the walls on the second floor and gymnasium as well as along the top of the windows on the first floor. The building windows are made with aluminum frames and 1” insulated glazing.

a darker decorative band running along the top of the walls on the second floor and gymnasium as well as along the top of the windows on the first floor. The building windows are made with aluminum frames and 1” insulated glazing.

The gymnasium and cafeteria wall are composed of the same system, but with minor modifications. The CMU in the gymnasium and cafeteria is 12” (as opposed to 8”) and the vapor retarder is replaced with a mastic vapor barrier.

The walls for the music room follow the typical construction, with the addition of fabric covered fiberglass acoustic wall panels on the inside. The fabric covered panels absorb sound much better than exposed CMU, which decreases the reverberation time for the room.

The walls for the exterior mechanical courtyard do not contain insulation, as both sides are exposed. Instead the wall is composed of 8” CMU with a solid grouted collar joint and brick façade on each side.

Roofing

Built-up asphalt roofing is used on top of the roofing insulation throughout the building. The insulation rests on topof the steel deck, and is made of two layers. The top layer slopes, in order to direct the water on the roof to the drains.

Sustainability Features

When entering the first floor, it is necessary to pass through two sets of doors on either end of the vestibule. The second set of doors is locked during the day, which forces visitors to pass through the reception area and sign in. At the start and end of the school day, these doors can be unlocked allowing the children to easily come and go. Although this is primarily a security feature, the double doors also functions as an air lock which minimizes warm air lost during the winter (and cold air during the summer) by occupants opening the entrance doors.

There are two energy recovery units (ERU) on the roof of the building. These are designed to allow the incoming air to absorb heat from the exhaust air. This reduces the energy load of the building, since the incoming air is heated by the exhaust air in addition to the heating coils.

Construction

Pershing Hill Elementary School is being delivered using a traditional design-bid-build approach with a multiple prime contract structure in which Jacobs Facilities, Inc. is acting as the construction manager. Because it is a public school project, the multiple prime approach is mandated by law. The owner holds 15 lump sum contracts with the specialty contractors, in addition to the contracts with the architect and construction manager. The specialty contractors won their contracts in a public bid, where the contract is awarded to the lowest qualified (defined as a company that has been in business for at least three years, and has completed at least three jobs of similar size and scope) bidder.

Pershing Hill Elementary School is located entirely within an US army base (Fort Meade). This results in challenges: for access for personnel, materials and equipment; coordinating with permitting authorities, as well as the authorities which have jurisdiction at the county level; and meeting additional contract requirements (e.g. in the event of a base lockdown). Anne Arundel County is very concerned with possible storm water runoff from construction sites. As such, two sediment control ponds are installed which will collect and trap the runoff.

Demolition of the existing building was required, as the new school will be built on the same site. The existing building contained hazardous materials including lead paint, mercury in the thermostats, and asbestos between the face brick and CMU walls. The abatement was performed by the abatement prime contractor, Delaware Cornerstone Builders, and the other demolition by the demolition prime contractor, Pleasants Construction. During construction, the students from Pershing Hill ES will be relocated to Meade Heights ES.

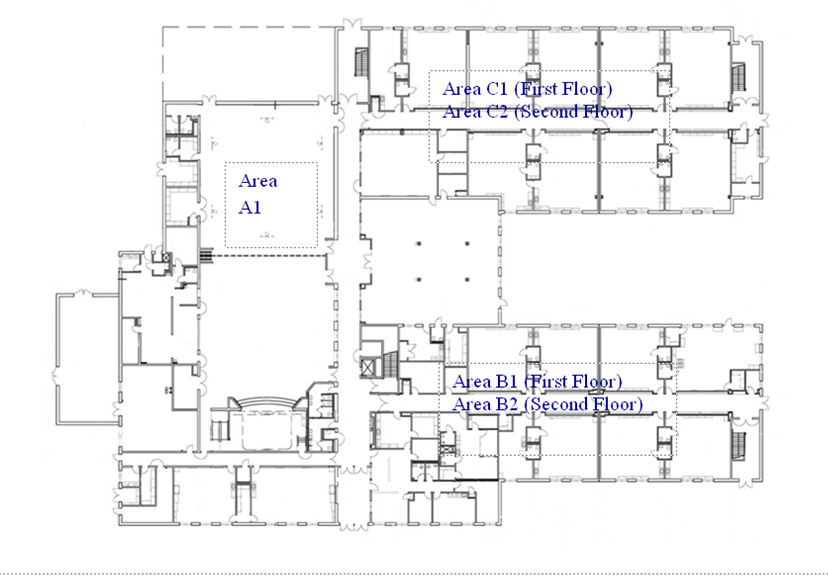

The reinforced concrete footings will be poured in area B first, followed by area A and area C last. Erection of the structural steel will begin in area A, followed by areas B and C. The finish sequences will follow the sequence A1, B1, C1, B2, C2 where the first floor is completed before work starts on the second floor. A graphic display of the various areas of the building is shown below.

Electrical

The electrical system includes both 277/480V and 120/208V distribution. Both are three phase with four wires. There is an electrical room located on the first floor across the hall from the mechanical room, and four other electrical closets throughout the building. The main switchboard carries a connected load of 1592.7 KVA and a demand load of 1276.7 KVA. An emergency intercom is available in each classroom.

Lighting

There are 52 different lighting fixture types on this project. Most are 277 volt; however there are also some that run on 120 volts. Fluorescent fixtures are primarily used, but there are also HID, incandescent, and LED lights used for specific purposes. All interior lighting must comply with local codes and zoning requirements as well as NFPA 70 and NFPA 101.

Mechanical

The building is divided into 11 zones in which the temperature can be controlled. The mechanical room is located on the first floor, adjacent to the cafeteria. The mechanical system included 2 boilers, 46 fan coil units, 6 ductless split system AC units, 6 rooftop air handling units and 2 rooftop air handling units with energy recovery. All rooftop air handling units run on 480V-3 phase power.

Structural

The foundation system on this project is cast in place concrete. The slab on grade is typically 5” thick concrete reinforced with welded wire fabric over a vapor barrier and 4” of washed gravel, however it is 6” thick concrete at the mechanical room. The top of the footings typically lie 2’ below the slab. The footings are reinforced and vary widely in size (from 11 to 99 sqft in area), but only vary between 1’ and 1’-6” in thickness. The concrete on this project typically must have a compressive strength of 3000psi at 28 days, but all concrete exposed to weather must have 4500psi and be air entrained.

A composite slab is used where the second floor slab is 3” thick normal weight concrete reinforced with welded wire fabric over galvanized form deck. W16X26 joists are used in areas B and C with W10x15 joists used along the corridors on the second floor and 18KCS2 joists are used with W5X16 joists to support the roof. The roof deck is 1 ½” type ‘B’ galvanized metal roof deck. Seven different sizes of HSS shaped columns are used

The concrete masonry shall have a minimum compressive strength of 1900 psi on the net area, and the brick shall have a minimum compressive strength of 3350 psi on the net area. Temporary scaffolding is used during the installation of the masonry. Masonry piers with vertical reinforcement are used which vary in size from 8”x16” to 19”x32” All piers are 100% solid (either solid block, or hollow block filled with 3000 psi grout).