General Building Data:

Name: SteelStacks Performing Arts Center

Location: Bethlehem, Pennsylvania

Building Occupant: ArtsQuest

Occupancy: A1

Size (sq. ft.): 67,167

Stories: 4 stories above grade

Total Height: 64 ft above grade

Dates of Construction (start to finish): January 2010 - April 2011

Actual Cost: $21 million (building)

$48 million (site)

Project Delivery Method: Design-Bid-Build

Type of Construction: IIA

Project Team:

Owner: ArtsQuest

Architect: Spillman Farmer Architects

Structural & Forensic Engineer: Barry Issett, Associates, Inc.

MEP: Brinjac Engineering

CM: Alvin H. Butz, Inc

Site/Civil Engineer: French and Parrello

Food Service: Porter Khouw Consulting, Inc

Acoustic: Acoustic Dimensions

Audio/Visual: AVI/SPL

Architecture:

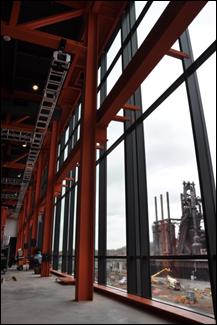

The SteelStacks Performing Arts Center (SSPAC) emphasizes the significance of the site through reflecting the importance of the historical Bethlehem Steel, which one stood in its location. This is accomplished through emphasizing the use of exposed structural steel and large, open atrium spaces, which helps the building towards its resemblance of the warehouse that once stood in its place. While maintaining some of the aesthetic values of the steel mill, the SSPAC uses a contemporary interpretation of old styles, bringing the history of the site into the new use as a commonplace for arts and culture to meet.

A textured wall of concrete panels mimics the steel manufacturing process, marking the entrance to the interior spaces, and welcoming the visitor into the lobby centered around a spiral stair. This space draws the visitor into the building, while bringing their gaze upwards into the first atrium, and then inwards, towards the commonplaces found on all floors. These spaces are connection points for the arts and cultures to meet - creative commons, theatres, and a mixed cafe and stage. This gives the idea of expansion going further into the space, resembling the spatial presentations seen in the original industrial plants.

Major National Model Codes: 2006 IBC

Zoning: I-R

Area and Yard Requirements (C-B Zone)

Historical Requirements:

The site was the previous home of Bethlehem Steel, which manufactured steel for many prominent structures throughout the country until 1995. In the city's attempt to redeem a large brownfield space , the SSPAC is hoping to spark an arts and cultural hub for the surrounding area.

Awaiting response from Architect on further details for design/development limitations and requirements.

Building Enclosure:

Building facade

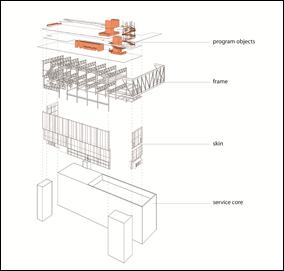

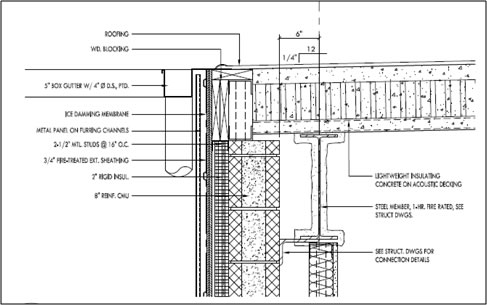

The main features of the facade are precast concrete panels with a textured finish, supported by the steel skeleton or hung from reinforced CMU walls. With the need for acoustical separation between spaces inside the building as well as isolation from the environment, this system gives the building this acoustical advantage through the facade and structure design. The panels also contribute to the building’s unique aesthetic, in partnership with the aluminum curtain wall system. This curtain wall system includes low E and fritted glazing along the northern facade, allowing for light entry throughout the atrium common spaces on all floors.

See the figures below, which display the acoustical design applied to the building enclosure and the precast concrete panels alongside the curtain wall system.

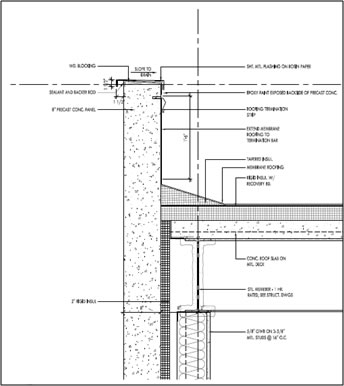

Roofing

The roofing system is a fabric-reinforced Thermoplastic Polyolefin (TPO), as the roof is not accessible to the public. This roofing is supported by an 8” reinforced concrete roof slab on metal decking or lightweight insulating concrete on acoustic decking, depending upon the location. The roof is designed to support the mechanical systems, which are upon the southern portion of the building.

Sustainability Features:

The SSPAC was designed for LEED silver, with the submission for this status in progress. Designs implemented the use of water and energy conservation for both public and back-of-house facilities, which impacted the equipment chosen. Considerations for sustainability in building and construction include the use of local manufacturing & recycled products, and waste management reduction. Other sustainability features incorporate space for local pedestrian and bike traffic seen throughout the exterior space and natural lighting seen within the various atrium spaces.

Structure:

Foundation:

French & Parrello Associates conducted field research on May 20, 2009, collecting the plan and topographic information necessary. The site of the SteelStacks Performing Arts Center (SSPAC) had an existing building, to be fully removed before start of construction. This demolition included the removal of the foundation and slab on the west side of the site. The location of an underground tunnel directly under the existing building was also taken into consideration when designing the foundation system for the SSPAC. The SSPAC is built above the original building portion that was demolished.

The soil bearing pressure has been recommended on the subsequent plans as a minimum of 3000 psf. The foundation was then determined to be a system of column piers and footings supporting a slab-on grade. The column footings varying in size from 3’0”x3’0” to 20’0”x20’0” and vary in depth from 1’0” to 4’2”. The variation in dimensions and depths of the column footings is due to the building design as well as the soil and other existing conditions that lead to settlement and strength issues. The foundations allow for a transfer of gravity loads into the soil through connection with the first floor.

Framing:

The main framing plan for the structure consists of a slab and deck floor system supported by beams with varying girders and trusses, following into columns that go into the foundation described above. Floor beams are spaced at a maximum of 7’6” and range from W10x12s to W24x55s, depending on the required loadings and spans of each space. The beams are also generally continuously braced, with ¾” x 4” long shear studs spaced along all beams connecting to the composite slabs. Trusses support larger spans in atrium and public spaces, while composite beams support the smaller spans for spaces such as hallways, meeting rooms, and back-of-house spaces. Columns are generally W12s, as the structural engineer focused on not only supporting the structure, but keeping the steel consistent dimensions. HSS columns were also used at varying locations, and varied from HSS4x4s to HSS10x10s.

Lateral System:

The main lateral force resisting system of this building varies per direction. In the North-South direction, the lateral system consists of shear walls. These shear walls are comprised of the precast concrete panels found along the exterior of the building. These panels are 8” thick normal weight concrete and are anchored with L5x5x5/16” to the structure for deck support and into the foundation as discussed and detailed previously. Braced frames along Column Line C in the East-West direction consist of the other component to the lateral framing system. These braced frames are comprised of W10x33s for diagonal members and W16x36s for horizontal members.

The lateral loads on the structure first impact the exterior components and shear walls. Where braced frames are concerned, this load travels through the horizontal members into the diagonal and vertical members. These loads all then continue into the foundation.

Construction

The 67, 167 ft2 steel frame and precast concrete panel Arts and Cultural Center consists of 4 stories. The Steel Stacks Performing Arts Center, with a finish elevation at 64 feet above grade, is a $48 million project. Construction was completed between January 2010 and April 2011, as a Design-Bid-Build project. Existing site conditions, such as utilities and previous building foundation and underground tunnel, impacted the construction procedures, and coordination was important between design and construction teams.

Electrical

The electricity in the 3-phase, 4 wire system is supplied into one transformer at 480/277V, entering through the service road of the first floor, into the main electrical room. This transformer drops the voltage and then transfers it to 200 A switchgears, located in the electrical rooms corresponding to each floor. Mechanical and lighting loads are primarily supplied at 480/277 V, while receptacles, theatrical lighting, and other loads are supplied at 208/120 V. A 200 kW back-up generator is located near the first floor electrical room.

Lighting

Lighting is generally run at 277V. The facade of the SSPAC is lit by wallwash metal halide fixtures. For spaces such as the Creative Commons, cinemas, and Blast Furnace room, incandescent pendants are most commonly utilized. These are supplied as 16” incandescent fixtures, varying from 50 watts to 165 watts supplied per fixture. This variation is due to the height and purpose of each space. Track lighting is also used in spaces overlooking atrium spaces, such as the Musikfest Cafe. For spaces that are not consistently in use, such as kitchens and other back of house spaces, recessed and surface lighting are used. These are generally (2) 4 foot T8 fluorescent lamps within each fixture at 32 watts.

Mechanical

The main storage location for the mechanical equipment is located on the mechanical roof, adjoining the fourth floor, with the exception of the unit for the Blast Furnace Room, located on the second floor. This air handling unit supplies 5300 CFM to this multipurpose room on the third floor.

Floors are divided into spaces, due to the various atriums between floors. The Creative Commons on the first floor, the small and large theaters, the kitchen area on the third floor, and the Musikfest Cafe on the third and fourth floor, are supplied air by variable air volume units located on the mechanical roof. These (6) rooftop units supply air at 1650 - 23500 CFM. Heat is provided by reheat exchangers, all located on the mechanical roof. Cooling is supplied through a direct expansion cooling system, at 150 total tons. (4) Energy recovery units are utilized to reduce cooling by 43.5 total tons, and reduce overall heating by 1,375,827 BTU/hr. These are also located on the mechanical roof.

Acoustics

Noise criteria were set for the Cinemas, Blast Furnace Room, Creativity Commons, and Musikfest Cafe ranging from RC-20 to RC-30, and were taken into consideration in multiple focuses of the design.

Due to the isolation of spaces required in relation to the noise criteria, the slab and decking for the third floor was controlled by acoustics, rather than strength or serviceability requirements, and resulted in an 8” thick system. Other considerations for acoustics are seen in the masonry walls surrounding the cinemas and the acoustic paneling in the Blast Furnace Room.

In terms of the mechanical systems, duct sound attenuators were specified for the interior AHU unit in the Blast Furnace Room, and rooftop units 2-5.

Fire Protection

The SteelStacks Performing Arts Center was designed in accordance with the IBC and NFPA for the utilized fire protection system. Structural walls, bearing walls, and floor construction were designed for a one-hour rating, with mechanical shafts and stairwells were rated for two-hour fire protection. A wet pipe fire suppression system was included in the fire protection design in accordance with NFPA Standard 13, and is utilized in fire suppression throughout the structure.

Transportation/Conveying Systems

Conveying systems for the SSPAC are seen in the series of elevators and stairs throughout the building. This includes (2) passenger elevators at the front entrance and (1) freight elevator at the back of the building. The main elevators are designed for a 4000 lb capacity and a speed of 150 fpm. The service elevator is designed for a 5000 lb capacity and a speed of 150 fpm. (3) Stairwells are located at the northeast, northwest, and southwest corners of the building and are the full height of the building. The fourth, a steel spiral stair, is located in the front entrance atrium. (2) Other staircases do not go the full height of the building. One open staircase connects the first and second floor atrium spaces for public use. The other is for use by Musikfest Cafe artists between the third floor stage and fourth floor.

Telecommunications

The telecommunications system for the SSPAC is a simple system that provides the necessary internet and communication capacities. Public phone, intercom, and emergency outlets are provided throughout the building. For cinema spaces, overhead projectors and communication access are provided.